Hello, again! Since its getting very dark at least in Finland, I'm thinking about fitting LED light to my pit bike so I can ride it at nighttime. How should I wire it up? I'm going to buy either 18W,36,48W led to my pit bike. seems like I have lighting coils because I have 2 yellow wires from the stator. I already have the 12v regulator, I have ordered Diode rectifier KBPC 5010 it should turn AC to DC. Should I fit the rectifier before the regulator? Another thing is that some riders recommend adding Capacitor to smooth out the DC power. Not sure what size cap should I order. I have taken look at the 63V 6800uF capacitor. I'm not electronic engineer or anything so not sure about the capsize and sort of stuff. Do I even need the capacitor not sure but in videos it makes the LED brighter? I have switched from old Mercedes 312cdi so they are at least good. I know how to wire the Regulator, switch and light but not sure should I put the rectifier first then cap, reg, switch, light. Big thanks in advance!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Adding LED to pitbike

- Thread starter Jope22

- Start date

Help Support Mini Dirt Bikes & Pit Bikes Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Rapidrob

Member

- Joined

- Jan 9, 2020

- Messages

- 12

- Reaction score

- 0

This will work on any minibike. How you do it and what you want it to look like is your choice. This I did to my AM Hawg Ty.

It was inexpensive,will last a very long time and is extremely bright. The lights do not very in intensity with engine speed.

Let there be light...head and tail light that is….

I wanted to electrify my AM Hawg Ty minibike and gathered together a few things to make it work as I wanted it to.

My plan was to install a LED Head Light, some sort of a tail light for others approaching from behind me at night or on the wooded trails. (The Dirt Bikers travel at very high speeds down the trails.)

I also wanted a way to charge my cell phone in case of a dead battery while in the Roaming Zones for hours at a time.

First things first, I source of power was needed. The engine is a HF Predator 212 a clone of the Honda GX200 series of engines. Parts interchange. A choice of one pair of coil ( Charging) or heavy duty two coils ( Lighting)are offered. Charging provides 30 Watts, Lighting 50 Watts or even a little more.

A three magnet flywheel would be needed as well.

The two coils will provide 4.1 amps just by themselves. For today's LED lamps that's a lot to play with

To boost the current ( Amps) a little, if need be, a small battery pack would be ideal. Also I wanted to run my cell phone charger

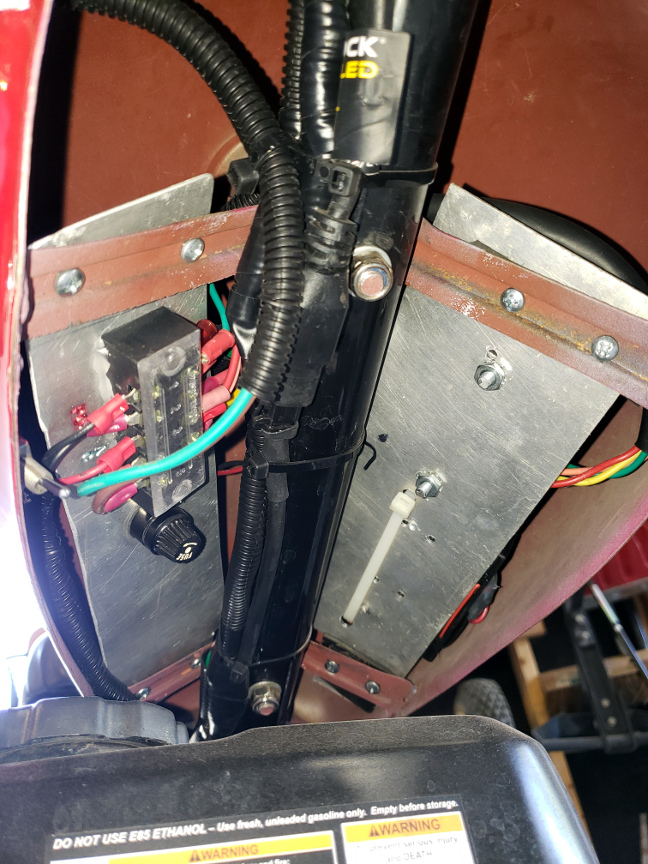

Now where to put all the things needed to build this system? Under the bikes phony gas tank.

Today's electronics are very small and powerful and best of all cheap to buy!

I then needed to find all the components to build the system. On line shopping sites will have all the parts you need. Do shop around for the best deals and lowest or free shipping. A little computer time can save you a lot of money. If your willing to wait for out of country shipping to show up, you can save even more.

So first things first, the Flywheel and Coils. There are real expensive and total junk. Read reviews and decide which ones you want. Make sure the parts will fit your engine. Some will not fit the HF Hemi engine.

Next is the head light. I found the brand new LED Spot Light from

Harbor Freight was perfect, small, powerful and built like a tank out of cast aluminum. With a coupon it is dirt cheap. ( under 20 bucks)

Next the tail light(s) were needed. I found two flashing Red LED lights that were made out of machined aluminum and shatter proof glass with all wiring and flasher module for 3 bucks shipped!

And boy are they bright!

Both head light and tail lights together draw less than 4½ Amps! That still keeps some Amps from the engine to play with without touching the current capability from the battery pack!

I made my battery pack by using batteries out of a laptop computer. The computer battery contained ten

18650 3.7 volt Li/Ion batteries. One was bad, the other nine were like new. These batteries carry a lot of current for their size, that is why they work so well in laptop computers.

A battery pack holder for these batteries is inexpensive and made well. I’m using a four cell holder with the he reason for this later on in this article. That being said, if your going to rough-it with your bike you should solder the batteries together.

Now for the voltages that are generated and rectified/ regulated by the bikes alternator and on board battery pack.

The stator of the engine ( the new flywheel and coils) produces AC voltage. This voltage will vary from about 5 volt at slow idle to over 22 volts at max speed. Even with a head light bulb rated for AC this is either too low or way too much voltage.

This voltage needs to be rectified through a full wave rectifier to a DC voltage. Since you cannot get ‘sometin fot nutin’ you will loose about 2 volts during the conversion to DC. You can do a ½ wave rectifier but the pulsating voltage is hard on LED’s.

The other half of the rectifier regulator is just that, a regulator. This device is set by electronics when the engine stator and battery pack is under full load ( Amps). If your running a 12 volt DC lighting system you want want the output voltage to 13.5 VDC. This will not only allow the light to run at its brightest it will also top off the battery pack and not overcharge it with all that extra voltage being generated as the engine speeds up. You really need a Rectifier/Regulator device if you want your lights and what ever else you power to last a long time.

You want to use wires that will carry your max load and not heat up and melt. For 99% of a head light and tail lights using a battery pack with stator 18 to 16 gauge wire will be large enough. If you’d like,14 gauge would give you more current carrying capability than you will probably will ever need.

You need a fuse that is 20% larger than your max load. ie, your drawing 3 Amps of current, use a 5 Amp fuse. Many small engine electrical systems will surge a little as a load is placed on them. This is hard on a standard fuse. A slow-blow fuse really helps prevent the fuse from failing during the surge.

Don’t throw in a large fuse, If your system is only capable of producing 5 Amps, putting a 10 Amp fuse is asking for trouble. The components will fail before the fuse blows.

Many In-Line fuse holders are weather resistant.

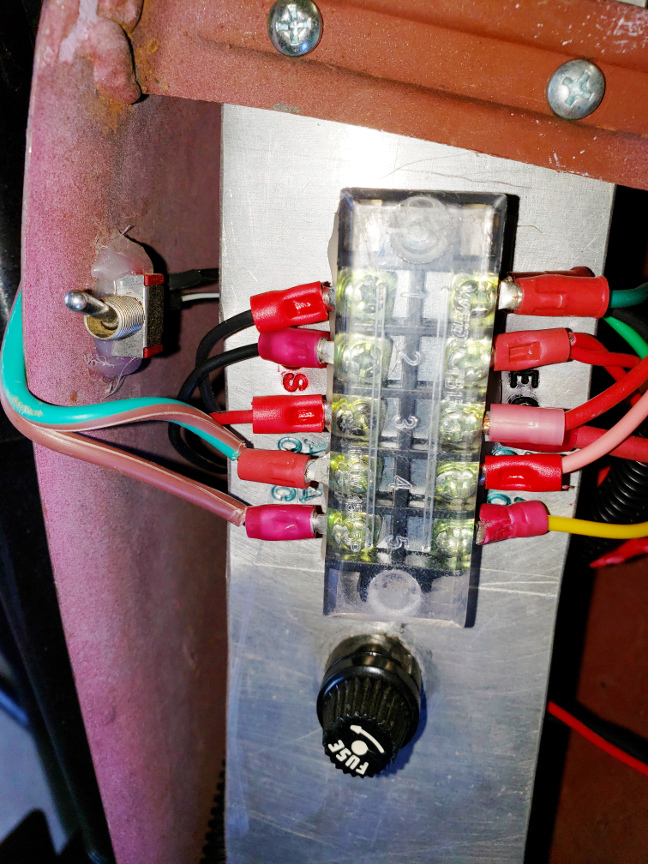

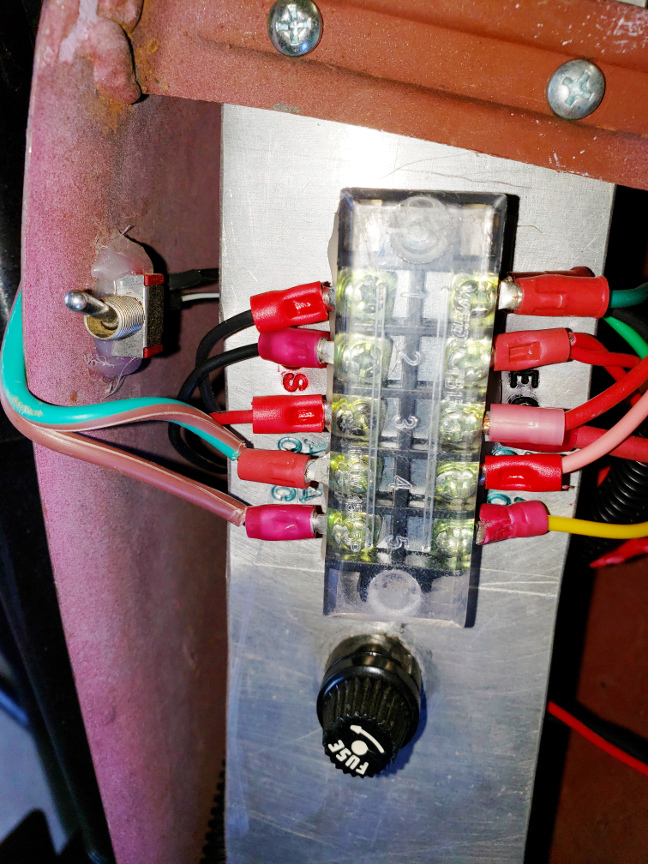

I’m a big fan of weather resistant Terminal Strips. By using these you terminate the wires using a Ring connector ( for vibration and minor shock/pulls) and you clearly can see which wire is on which screw terminal. This is a much better way to organize your wiring and looks a lot better than Wire Nuts or globs of electrical tape.

Since the bike is run outside all year long, I also place the wiring inside of Split Wiring Loom plastic wiring conduit. They come in colors if you want. HF has it in ten foot rolls for cheap.

The lights are controlled by a handlebar switch. The switch is rated for three times more current than my lights draw. You can use a relay to allow the current to go through it rather than the switch. But relays require current to turn on and stay on. Solid state relays require less current but they must be DC voltage rated in order to work properly.

I prefer a “Kill-Switch” to turn on/off the voltage from the R/R and the battery pack. This will keep the battery from draining while the bike is parked in the garage.

The switch is rated for current above the max load by 50% or more. This way it should never fail in use.

I hide the switch under the phony gas tank,but easy to turn on even wearing gloves.

You will most likely have electrical splices to make. If you do use Butt-Splices or other automotive connectors to help protect the exposed wire ends from the elements. I seal all my connections,once they have been tested, with hot melt glue.

Keep your connections away from water and mud if at all possible. Same goes for high temperatures touching the wiring.

As I have written, I’m hiding my electronic components under my phony gas tank. You may not have one. But you do have a seat, and in most cases an area in front,at the bottom of your engine you can store your electronics. A plastic or metal container is all you need. Many types and sizes are available on the www.

Your bike will produce many different frequencies of vibrations. Because of this I only recommend Ring Terminals. Don’t be lazy/cheap/could careless and just use bare wires tapped together or under a screw head. They will shake loose. Taped wire nuts can be used but look like crap,they trap water and dirt and will cause the wires to corroded and fail.

I an including photo’s of my lay out and will describe the point-to-point wiring. Keep it simple and well marked or written down for later spireas. Cell phone photos are a god send.

At the time of this writing I have put over 25 miles off road on the electrical system with the lights running at all times the engine is. So far no problems on the trail.

One component I mentioned as good to use in an earlier post turned out to be crap. I went with a much

heavier duty device as listed in the parts breakdown.

end Part 1

It was inexpensive,will last a very long time and is extremely bright. The lights do not very in intensity with engine speed.

Let there be light...head and tail light that is….

I wanted to electrify my AM Hawg Ty minibike and gathered together a few things to make it work as I wanted it to.

My plan was to install a LED Head Light, some sort of a tail light for others approaching from behind me at night or on the wooded trails. (The Dirt Bikers travel at very high speeds down the trails.)

I also wanted a way to charge my cell phone in case of a dead battery while in the Roaming Zones for hours at a time.

First things first, I source of power was needed. The engine is a HF Predator 212 a clone of the Honda GX200 series of engines. Parts interchange. A choice of one pair of coil ( Charging) or heavy duty two coils ( Lighting)are offered. Charging provides 30 Watts, Lighting 50 Watts or even a little more.

A three magnet flywheel would be needed as well.

The two coils will provide 4.1 amps just by themselves. For today's LED lamps that's a lot to play with

To boost the current ( Amps) a little, if need be, a small battery pack would be ideal. Also I wanted to run my cell phone charger

Now where to put all the things needed to build this system? Under the bikes phony gas tank.

Today's electronics are very small and powerful and best of all cheap to buy!

I then needed to find all the components to build the system. On line shopping sites will have all the parts you need. Do shop around for the best deals and lowest or free shipping. A little computer time can save you a lot of money. If your willing to wait for out of country shipping to show up, you can save even more.

So first things first, the Flywheel and Coils. There are real expensive and total junk. Read reviews and decide which ones you want. Make sure the parts will fit your engine. Some will not fit the HF Hemi engine.

Next is the head light. I found the brand new LED Spot Light from

Harbor Freight was perfect, small, powerful and built like a tank out of cast aluminum. With a coupon it is dirt cheap. ( under 20 bucks)

Next the tail light(s) were needed. I found two flashing Red LED lights that were made out of machined aluminum and shatter proof glass with all wiring and flasher module for 3 bucks shipped!

And boy are they bright!

Both head light and tail lights together draw less than 4½ Amps! That still keeps some Amps from the engine to play with without touching the current capability from the battery pack!

I made my battery pack by using batteries out of a laptop computer. The computer battery contained ten

18650 3.7 volt Li/Ion batteries. One was bad, the other nine were like new. These batteries carry a lot of current for their size, that is why they work so well in laptop computers.

A battery pack holder for these batteries is inexpensive and made well. I’m using a four cell holder with the he reason for this later on in this article. That being said, if your going to rough-it with your bike you should solder the batteries together.

Now for the voltages that are generated and rectified/ regulated by the bikes alternator and on board battery pack.

The stator of the engine ( the new flywheel and coils) produces AC voltage. This voltage will vary from about 5 volt at slow idle to over 22 volts at max speed. Even with a head light bulb rated for AC this is either too low or way too much voltage.

This voltage needs to be rectified through a full wave rectifier to a DC voltage. Since you cannot get ‘sometin fot nutin’ you will loose about 2 volts during the conversion to DC. You can do a ½ wave rectifier but the pulsating voltage is hard on LED’s.

The other half of the rectifier regulator is just that, a regulator. This device is set by electronics when the engine stator and battery pack is under full load ( Amps). If your running a 12 volt DC lighting system you want want the output voltage to 13.5 VDC. This will not only allow the light to run at its brightest it will also top off the battery pack and not overcharge it with all that extra voltage being generated as the engine speeds up. You really need a Rectifier/Regulator device if you want your lights and what ever else you power to last a long time.

You want to use wires that will carry your max load and not heat up and melt. For 99% of a head light and tail lights using a battery pack with stator 18 to 16 gauge wire will be large enough. If you’d like,14 gauge would give you more current carrying capability than you will probably will ever need.

You need a fuse that is 20% larger than your max load. ie, your drawing 3 Amps of current, use a 5 Amp fuse. Many small engine electrical systems will surge a little as a load is placed on them. This is hard on a standard fuse. A slow-blow fuse really helps prevent the fuse from failing during the surge.

Don’t throw in a large fuse, If your system is only capable of producing 5 Amps, putting a 10 Amp fuse is asking for trouble. The components will fail before the fuse blows.

Many In-Line fuse holders are weather resistant.

I’m a big fan of weather resistant Terminal Strips. By using these you terminate the wires using a Ring connector ( for vibration and minor shock/pulls) and you clearly can see which wire is on which screw terminal. This is a much better way to organize your wiring and looks a lot better than Wire Nuts or globs of electrical tape.

Since the bike is run outside all year long, I also place the wiring inside of Split Wiring Loom plastic wiring conduit. They come in colors if you want. HF has it in ten foot rolls for cheap.

The lights are controlled by a handlebar switch. The switch is rated for three times more current than my lights draw. You can use a relay to allow the current to go through it rather than the switch. But relays require current to turn on and stay on. Solid state relays require less current but they must be DC voltage rated in order to work properly.

I prefer a “Kill-Switch” to turn on/off the voltage from the R/R and the battery pack. This will keep the battery from draining while the bike is parked in the garage.

The switch is rated for current above the max load by 50% or more. This way it should never fail in use.

I hide the switch under the phony gas tank,but easy to turn on even wearing gloves.

You will most likely have electrical splices to make. If you do use Butt-Splices or other automotive connectors to help protect the exposed wire ends from the elements. I seal all my connections,once they have been tested, with hot melt glue.

Keep your connections away from water and mud if at all possible. Same goes for high temperatures touching the wiring.

As I have written, I’m hiding my electronic components under my phony gas tank. You may not have one. But you do have a seat, and in most cases an area in front,at the bottom of your engine you can store your electronics. A plastic or metal container is all you need. Many types and sizes are available on the www.

Your bike will produce many different frequencies of vibrations. Because of this I only recommend Ring Terminals. Don’t be lazy/cheap/could careless and just use bare wires tapped together or under a screw head. They will shake loose. Taped wire nuts can be used but look like crap,they trap water and dirt and will cause the wires to corroded and fail.

I an including photo’s of my lay out and will describe the point-to-point wiring. Keep it simple and well marked or written down for later spireas. Cell phone photos are a god send.

At the time of this writing I have put over 25 miles off road on the electrical system with the lights running at all times the engine is. So far no problems on the trail.

One component I mentioned as good to use in an earlier post turned out to be crap. I went with a much

heavier duty device as listed in the parts breakdown.

end Part 1

Rapidrob

Member

- Joined

- Jan 9, 2020

- Messages

- 12

- Reaction score

- 0

Part 2

Important notes:

If you use two CHARGING charging coils to power your light, one leg of each coil is shorted to engine ground. This is the only way the stator will produce AC voltage. This will make the engine and the bikes frame very “noisy” electronically and may cause all sorts of problems/failures to your lighting components IF you use the engine or frame as electrical ground for DC voltage.

This system would be 100% safe to use IF you go to a battery pack for an electrical ground. This works very well but uses more wires and connectors.

If you are using the two-coil LIGHTING system the output wires are NOT grounded to the engine or the bikes frame. This is ideal for an more elaborate higher current ( Amps) loaded system.

This system is perfect for running Cell-phone charges, GPS system, etc as it is very electrically quite. I bought a tiny 12VDC to 5 VDC converter with a wireless high current charger and I just clip the phone in the holder and let it charge in 30 minutes or less.

No photos in this post of the charger as most of you would never need to use it. check out my other post on the charger.

You CAN ground the Negative wires to the engine or bikes frame to save wiring and make the install easier,neater to do

I still go the the battery directly to prevent later corrosion problems with grounds that will happen over time with where you live.

I’m now using the Four wire Rectifier/ Regulator for Chinese motorcycles scooters that is idea to use for our needs.

You MUST have a battery pack in order to use this device. The R/R looks for a feed back on one wire coming from the battery Positive. Failure to provide this and the device will not function at all.

By using a small 18650 ( or the like) Li/Ion four cell battery pack, the device works perfectly and will never overcharge the four batteries ( 14.8 VDC) as the output of the R/R under load is 13.5 volts. In rough riding I solder the batteries together. Easy and safe to do. Youtube has many Vids on how to do this.

So far this has worked out really well. There is no surge of voltage as the engine speeds up and the lights stay the same brightness at all times even at slow idle.

End part 2

Important notes:

If you use two CHARGING charging coils to power your light, one leg of each coil is shorted to engine ground. This is the only way the stator will produce AC voltage. This will make the engine and the bikes frame very “noisy” electronically and may cause all sorts of problems/failures to your lighting components IF you use the engine or frame as electrical ground for DC voltage.

This system would be 100% safe to use IF you go to a battery pack for an electrical ground. This works very well but uses more wires and connectors.

If you are using the two-coil LIGHTING system the output wires are NOT grounded to the engine or the bikes frame. This is ideal for an more elaborate higher current ( Amps) loaded system.

This system is perfect for running Cell-phone charges, GPS system, etc as it is very electrically quite. I bought a tiny 12VDC to 5 VDC converter with a wireless high current charger and I just clip the phone in the holder and let it charge in 30 minutes or less.

No photos in this post of the charger as most of you would never need to use it. check out my other post on the charger.

You CAN ground the Negative wires to the engine or bikes frame to save wiring and make the install easier,neater to do

I still go the the battery directly to prevent later corrosion problems with grounds that will happen over time with where you live.

I’m now using the Four wire Rectifier/ Regulator for Chinese motorcycles scooters that is idea to use for our needs.

You MUST have a battery pack in order to use this device. The R/R looks for a feed back on one wire coming from the battery Positive. Failure to provide this and the device will not function at all.

By using a small 18650 ( or the like) Li/Ion four cell battery pack, the device works perfectly and will never overcharge the four batteries ( 14.8 VDC) as the output of the R/R under load is 13.5 volts. In rough riding I solder the batteries together. Easy and safe to do. Youtube has many Vids on how to do this.

So far this has worked out really well. There is no surge of voltage as the engine speeds up and the lights stay the same brightness at all times even at slow idle.

End part 2

Rapidrob

Member

- Joined

- Jan 9, 2020

- Messages

- 12

- Reaction score

- 0

Part 3

Lets start the build. Hopefully you have read my post up to this point. If you have not, back-up and do so. Otherwise you will be confused and lost as to what to do and why.

I will edit the instructions to the best of my ability. I am not responsible for any damage to your bike you may cause due to mistakes made or short cuts taken.

Parts list ( as I needed for my bike) by Item number.

Item One:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=183596077964

Item two:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=192962962278

* you can use either Two Charging coils ( 30 Watts) or two Lighting coils ( 50 Watts) your call.

Item Three:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=361061645928

This was a great deal and was well made and balanced perfectly. It fits the Non-Hemi HF 212 clone engine.

Item Four:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=282886812213

These two red lights are perfect warning or even brake lights. They are made from machined aluminum and hardened glass . When ON, they flash several times a second and are very bright! For three bucks!

They were easy to install and make weather proof.

Item Five

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=264117516273

Very well made and will carry more current (Amps) than you will ever need or use. Weatherproof to boot.

Item Six:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=291722900739

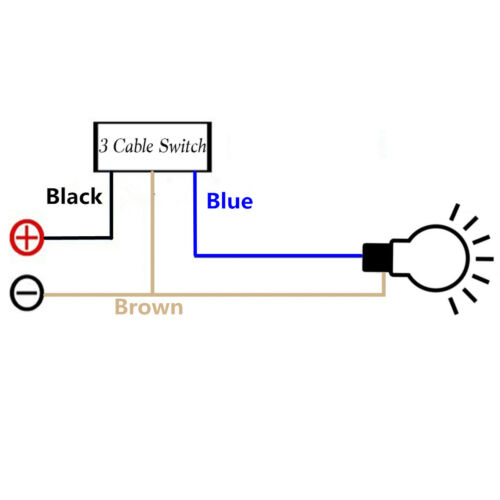

Looks cool very well made and can handle ten amps. You must follow my instructions on how to wire this switch with an LED in it or it will not work.

Item Seven:

https://www.treatland.tv/honda-NC50...brake-switch-p/brake-switch-35340-gan-620.htm

My single Brake Lever ( on the left side,handlebar) had a hole for a Brake Light Switch. I’m sure many do as well. This Honda switch fit like a glove with .002 of plastic in the rough cast handle hole removed.

Item Eight:

https://www.harborfreight.com/3-in-LED-Spot-Light-64323.html

This small LED light is very powerful. It will throw a beam of light 340 yards! ***

Bad, don't use:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=263780004555

I did recommend this device in an earlier post. It will handle a lighter Amp load,but did not handle a surge of current and burned out in a few seconds. I did not know this would happen. Sorry.

Now you will need at least a few more parts. I had them on hand. All are easy to find,you may have them on hand already.

1. A terminal strip. I used a 5-screw one. ( minimum size needed)

2. A fuse holder

3. Battery On/Off switch

4. Ring terminals for your wires

5. 16/18 gauge wiring. ( 14 gauge wiring would last for decades)

6. Butt-splices

7. Hot melt glue gun.

8. Rubber gasket material for vibration isolation of mounted parts.

9. Aluminum sheet, steel sheeting, heavy plastic sheeting, wood, what ever to mount the parts onto under the phony gas tank.**

This addition to your bike takes common hand tools, elbow grease and about six hours of your life.

You MUST have a DVM or other electrical Voltage meter for this build.They are so cheap to buy today there is no reason you do not have one.

It is EASY to do and very well rewarding when you light up the trail/road at night. It looks cool and may save your life.

Lets start the build. Hopefully you have read my post up to this point. If you have not, back-up and do so. Otherwise you will be confused and lost as to what to do and why.

I will edit the instructions to the best of my ability. I am not responsible for any damage to your bike you may cause due to mistakes made or short cuts taken.

Parts list ( as I needed for my bike) by Item number.

Item One:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=183596077964

Item two:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=192962962278

* you can use either Two Charging coils ( 30 Watts) or two Lighting coils ( 50 Watts) your call.

Item Three:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=361061645928

This was a great deal and was well made and balanced perfectly. It fits the Non-Hemi HF 212 clone engine.

Item Four:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=282886812213

These two red lights are perfect warning or even brake lights. They are made from machined aluminum and hardened glass . When ON, they flash several times a second and are very bright! For three bucks!

They were easy to install and make weather proof.

Item Five

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=264117516273

Very well made and will carry more current (Amps) than you will ever need or use. Weatherproof to boot.

Item Six:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=291722900739

Looks cool very well made and can handle ten amps. You must follow my instructions on how to wire this switch with an LED in it or it will not work.

Item Seven:

https://www.treatland.tv/honda-NC50...brake-switch-p/brake-switch-35340-gan-620.htm

My single Brake Lever ( on the left side,handlebar) had a hole for a Brake Light Switch. I’m sure many do as well. This Honda switch fit like a glove with .002 of plastic in the rough cast handle hole removed.

Item Eight:

https://www.harborfreight.com/3-in-LED-Spot-Light-64323.html

This small LED light is very powerful. It will throw a beam of light 340 yards! ***

Bad, don't use:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335845805&icep_item=263780004555

I did recommend this device in an earlier post. It will handle a lighter Amp load,but did not handle a surge of current and burned out in a few seconds. I did not know this would happen. Sorry.

Now you will need at least a few more parts. I had them on hand. All are easy to find,you may have them on hand already.

1. A terminal strip. I used a 5-screw one. ( minimum size needed)

2. A fuse holder

3. Battery On/Off switch

4. Ring terminals for your wires

5. 16/18 gauge wiring. ( 14 gauge wiring would last for decades)

6. Butt-splices

7. Hot melt glue gun.

8. Rubber gasket material for vibration isolation of mounted parts.

9. Aluminum sheet, steel sheeting, heavy plastic sheeting, wood, what ever to mount the parts onto under the phony gas tank.**

This addition to your bike takes common hand tools, elbow grease and about six hours of your life.

You MUST have a DVM or other electrical Voltage meter for this build.They are so cheap to buy today there is no reason you do not have one.

It is EASY to do and very well rewarding when you light up the trail/road at night. It looks cool and may save your life.

Rapidrob

Member

- Joined

- Jan 9, 2020

- Messages

- 12

- Reaction score

- 0

Part 4

***The Spot Light being used is not legal in any state for on road use. Do not stare into the light while on running at 12 VDC. It will temporally blind you.

READ THIS: For the rest of my instructions when I say or show Ground or Common, I mean the bikes frame or engine ground or go directly back to the battery pack common ( Negative) this will vary to the Charging Grounded coils or the Lighting Floating ( UN-Grounded ) coils you use. Don't cross these up.

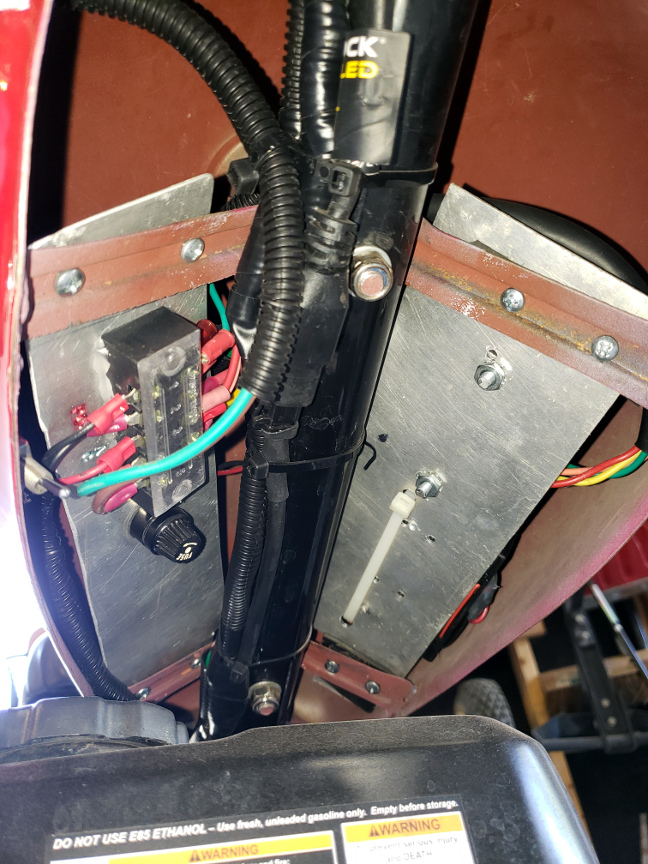

Here is my wired up phony gas tank. All parts are mounted to scrap aluminum plates and those are rubber mounted to prevent vibration damage.

One one plate are the Terminal strip and fuse holder. Next to the plate and glued to the side of the phony tank is the main power on/off switch.

Notice all parts clear the main support bar of the minibike.

***The Spot Light being used is not legal in any state for on road use. Do not stare into the light while on running at 12 VDC. It will temporally blind you.

READ THIS: For the rest of my instructions when I say or show Ground or Common, I mean the bikes frame or engine ground or go directly back to the battery pack common ( Negative) this will vary to the Charging Grounded coils or the Lighting Floating ( UN-Grounded ) coils you use. Don't cross these up.

Here is my wired up phony gas tank. All parts are mounted to scrap aluminum plates and those are rubber mounted to prevent vibration damage.

One one plate are the Terminal strip and fuse holder. Next to the plate and glued to the side of the phony tank is the main power on/off switch.

Notice all parts clear the main support bar of the minibike.

Rapidrob

Member

- Joined

- Jan 9, 2020

- Messages

- 12

- Reaction score

- 0

Weather resistant terminal strip and gasket sealed fuse holder.

The other plate is holding the Rectifier/Regulator and home made soldered battery pack. The BP is held in place with a strong Ty-Rap.

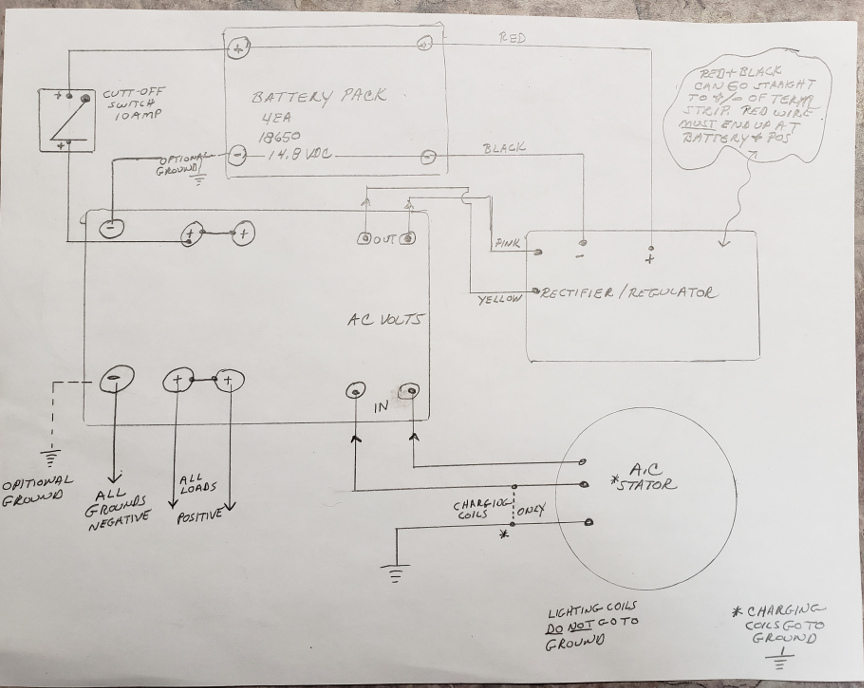

Here is a very simple schematic of how to get the AC to the terminal strip and then converted to DC for the lights.

What I did not show was the mounting of the fuse. Some folks see a schematic drawing and start to have 'Brain Pain" which is not needed.It really is a simple thing to do. I will help with any questions. If I made a mistake,please let me know.

OK, lower right hand corner is the Stator of the engine providing AC voltage. The CHARGING coils are GROUNDED and have to be in order to work the way they are wound at the factory. Because Ground must be used ( engine and bike frame) I do NOT recommend you use bike Ground for your DC voltage. The AC "noise will cause problems in the future.

If you are using the LIGHTING coils, NO wires go to Ground. The AC voltages Float in space. Both wires go directly to the R/R.

Now moving to the center of the page the AC comes into the terminal strip at the bottom right, through the strip bars and out to the R/R.

I'm using the cheap and common FOUR wire R/R. The wires from the one I post are Yellow,Pink,Green and Red. Yellow and Pink get the AC from the terminal strip coming from the Stator. The Red and Green wires are DC Positive and Negative. Some colors may be changed without notice. Do a search and there will be wire colors on the WWW that show you what you have.

Now the battery cut-off switch. I cut the Positive coming from the battery AND the R/R before it gets to the terminal strip. The switch is rated 50% greater than the lights maximum load. The switch is hot-melt glued to the side of the gas tank. The terminals are insulated from ground. The output from the Switch goes to and through the fuse holder. This protects everything from a dead short to ground. The fuse is always 20% greater than the maximum load from the lights. Use a slow-blow fuse if you can.

As for Ground ( common) for DC volts, you CAN with the Lighting Coils use chassis Ground or Engine ground. This will save wiring and make a neater wiring harness.

For the Charging coils I recommend you go straight to the battery or Negative on the terminal strip. The battery makes a good "filter" for AC noise coming from the two grounded coils.

Black to Now for the Head light switch. It has a LED diode in it's handle. You do not wire it as if it were a simple On/Off switch the color codes are not what you are used to. it is wired this way:

the battery or Positive terminal of the terminal strip. Black is not ground with this switch it is +Positive!

Blue is Positive switched going to the Positive + red wire of the Head light.

Brown is the switches Ground for the LED and the Black Ground wire for the head light. I tie these two wires together and go back to battery Negative rather than chassis ground. (If the light does not work it will be the chassis ground is poor,that is why I do not use chassis ground anymore).

Now for the head Light I'm using Harbor Freights Spot Light.

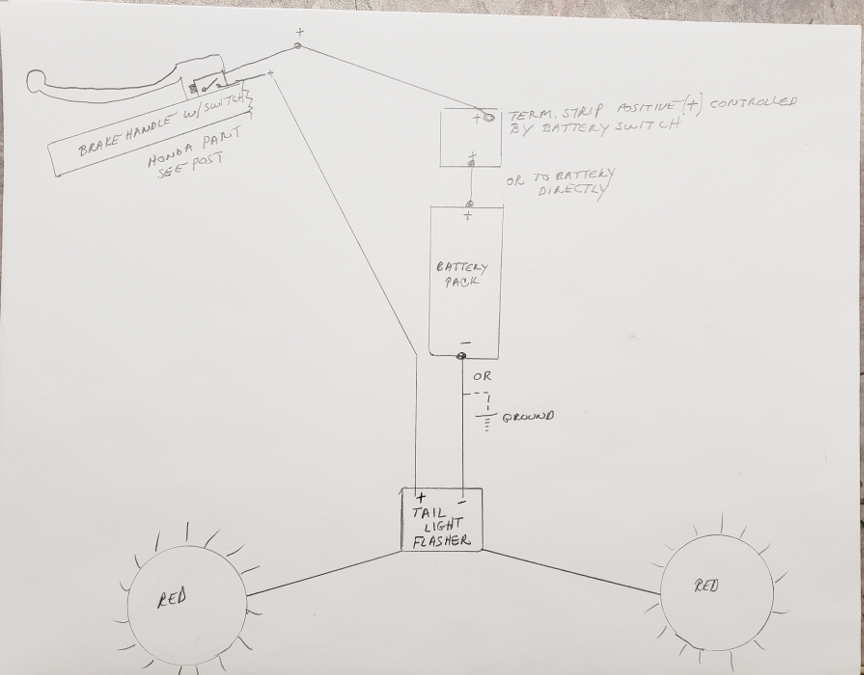

These flashing RED LED's are very bright. They clearly can be seen in daylight. you could just have them flashing all the time or go through a brake handle of your minibike.

I'm using this Honda Brake Light Switch. It fits the Chinese brake handle very well with a little work. It took me five minutes to mount it.

How it woks is very simple to wire up:

This brake light works with the Head Light off. Any time you start to close the brake handle the rear lights will flash until the handle is let go. I did wire it through the Battery Switch so the brake lights are dead with the switch turned off.

I cover a lot of ground ( no pun intended) with this post. Don't be afraid to wire up you bike for lights or what ever you need power for.

Ask questions if you are not sure or do something wrong. If you "let the smoke out" you have fried something. If it doesn't work ask me or others here for help.

Have your meter in hand and we will have it going in no time.

Rob.

The other plate is holding the Rectifier/Regulator and home made soldered battery pack. The BP is held in place with a strong Ty-Rap.

Here is a very simple schematic of how to get the AC to the terminal strip and then converted to DC for the lights.

What I did not show was the mounting of the fuse. Some folks see a schematic drawing and start to have 'Brain Pain" which is not needed.It really is a simple thing to do. I will help with any questions. If I made a mistake,please let me know.

OK, lower right hand corner is the Stator of the engine providing AC voltage. The CHARGING coils are GROUNDED and have to be in order to work the way they are wound at the factory. Because Ground must be used ( engine and bike frame) I do NOT recommend you use bike Ground for your DC voltage. The AC "noise will cause problems in the future.

If you are using the LIGHTING coils, NO wires go to Ground. The AC voltages Float in space. Both wires go directly to the R/R.

Now moving to the center of the page the AC comes into the terminal strip at the bottom right, through the strip bars and out to the R/R.

I'm using the cheap and common FOUR wire R/R. The wires from the one I post are Yellow,Pink,Green and Red. Yellow and Pink get the AC from the terminal strip coming from the Stator. The Red and Green wires are DC Positive and Negative. Some colors may be changed without notice. Do a search and there will be wire colors on the WWW that show you what you have.

Now the battery cut-off switch. I cut the Positive coming from the battery AND the R/R before it gets to the terminal strip. The switch is rated 50% greater than the lights maximum load. The switch is hot-melt glued to the side of the gas tank. The terminals are insulated from ground. The output from the Switch goes to and through the fuse holder. This protects everything from a dead short to ground. The fuse is always 20% greater than the maximum load from the lights. Use a slow-blow fuse if you can.

As for Ground ( common) for DC volts, you CAN with the Lighting Coils use chassis Ground or Engine ground. This will save wiring and make a neater wiring harness.

For the Charging coils I recommend you go straight to the battery or Negative on the terminal strip. The battery makes a good "filter" for AC noise coming from the two grounded coils.

Black to Now for the Head light switch. It has a LED diode in it's handle. You do not wire it as if it were a simple On/Off switch the color codes are not what you are used to. it is wired this way:

the battery or Positive terminal of the terminal strip. Black is not ground with this switch it is +Positive!

Blue is Positive switched going to the Positive + red wire of the Head light.

Brown is the switches Ground for the LED and the Black Ground wire for the head light. I tie these two wires together and go back to battery Negative rather than chassis ground. (If the light does not work it will be the chassis ground is poor,that is why I do not use chassis ground anymore).

Now for the head Light I'm using Harbor Freights Spot Light.

These flashing RED LED's are very bright. They clearly can be seen in daylight. you could just have them flashing all the time or go through a brake handle of your minibike.

I'm using this Honda Brake Light Switch. It fits the Chinese brake handle very well with a little work. It took me five minutes to mount it.

How it woks is very simple to wire up:

This brake light works with the Head Light off. Any time you start to close the brake handle the rear lights will flash until the handle is let go. I did wire it through the Battery Switch so the brake lights are dead with the switch turned off.

I cover a lot of ground ( no pun intended) with this post. Don't be afraid to wire up you bike for lights or what ever you need power for.

Ask questions if you are not sure or do something wrong. If you "let the smoke out" you have fried something. If it doesn't work ask me or others here for help.

Have your meter in hand and we will have it going in no time.

Rob.

$49.99

$59.99

Kids Dirt Bike Gear-Youth Motorcycle Motocross Armor Suit for Cylcing,Skateboard,Ski,ATV. Back Chest Elbows Knees Protector.

GuguzhichenStore

$59.90

MMG Set of 2 Mini Dirt Bike Knobby Tire 2.50/10 Front or Rear Tube Type Off Road Motocross Pattern

Powersports Depot

$2.64

$3.99

Just Gonna Send It Sticker - Funny car Window Sticker-UV Protected-Waterproof!

Made in U.S.A

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)

![Flaviao Motorcycle Phone Mount, Bike Phone Holder [Not Block Camera] for Electric Scooter Mountain Dirt Bike and Motorcycle Compatible with 4''-7'' Wide Smartphones](https://m.media-amazon.com/images/I/41oBHGeu9YL._SL500_.jpg)

![LISEN Bike Phone Holder, [2024 Upgrade] Motorcycle Phone Mount, Bicycle Phone Holder, Handlebar Phone Mount, for iPhone Bike Mount, Bike Accessories, Bicycle Accessories for iPhone 4.7-7"Phone, Black](https://m.media-amazon.com/images/I/41FJGrZQ5ML._SL500_.jpg)