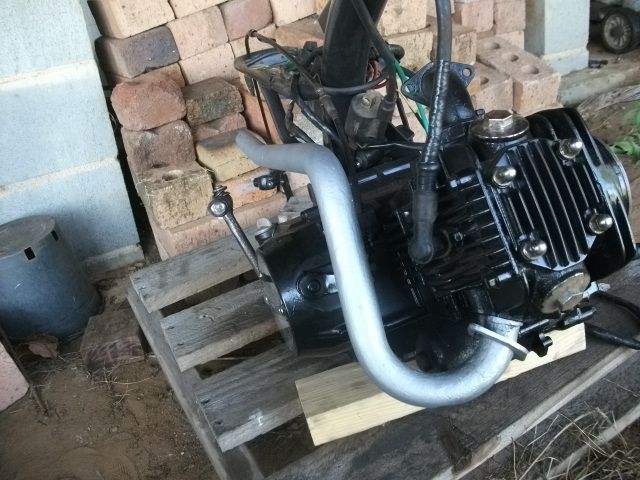

my67xr

Miniriders Legend and Master Spanner Spinning Mode

warming up the engine first can help release rust too, expansion may cause the bond of rust to break.

i use it a lot with panel beating, if you have a propane torch or even a heat gun, get the stud as hot as you can, and melt some candle wax onto it.

it will penetrate down the threads and help the nut to come loose.

if the studs undo from the head, then just place them with some brand new ones.

i use it a lot with panel beating, if you have a propane torch or even a heat gun, get the stud as hot as you can, and melt some candle wax onto it.

it will penetrate down the threads and help the nut to come loose.

if the studs undo from the head, then just place them with some brand new ones.

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)

![LISEN Bike Phone Holder, [2024 Upgrade] Motorcycle Phone Mount, Bicycle Phone Holder, Handlebar Phone Mount, Dirt Bike Accessories, Bicycle Accessories, Gifts for Men for iPhone 4.7-7" Phone, Black](https://m.media-amazon.com/images/I/41FJGrZQ5ML._SL500_.jpg)