Cactus Jack

Master Spanner Spinner

- Joined

- Jan 18, 2007

- Messages

- 2,742

- Reaction score

- 53

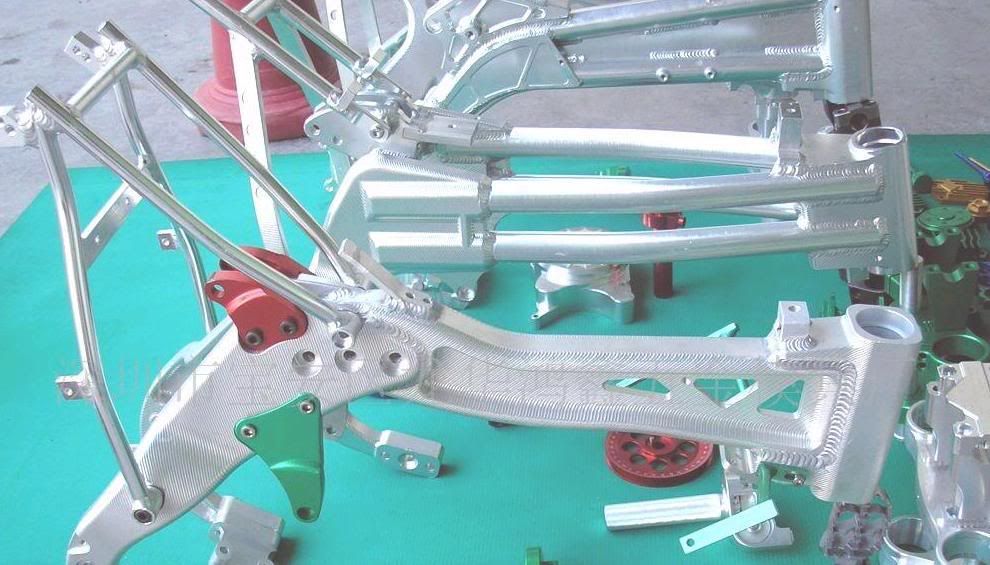

The Atomic Reign 150M's look OK ...... That alloy frame you posted a pic of would be good if they left a 10 mm thick web in the centre of the back bone and made the top and bottom parts thicker (like an "I" beam) instead of chopping all those diamond shaped holes thru them ..... You only need to take a look at the shape of railway line and the massive weight and flexing it can handle to realise that "I" beams are super strong .... (girder , conrods , spanners etc)

The Motovert Pro alloy frames are pretty impressive when it comes to strength and design ..... has anyone seen one of those break or crack thru the spine yet ??????? It's fricken hard to find pics of a bare frame though .....

The Motovert Pro alloy frames are pretty impressive when it comes to strength and design ..... has anyone seen one of those break or crack thru the spine yet ??????? It's fricken hard to find pics of a bare frame though .....

Last edited:

![2 Pack Bike Phone Holder Mount [2024 Upgraded Gift Set]- 3S Easy Install, Motorcycle Phone Mount Universal Handlebar, Cell Phone Holder Fit for EBikes Electric Scooter Dirt, Bike Accessories for Adult](https://m.media-amazon.com/images/I/41JK0xwDupL._SL500_.jpg)

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)