ok, i hate to say it but i totally Disagree with most he has told you...

the valves HAVE to be the same lenght..ie from valve tip to collet groove and from collet groove to valve head..

if you use longer valves you are going to change the rocker geometry and possibly cause increased cam and valve tip wear...

for longer valves to work you would also need longer rockers..

to explain why...

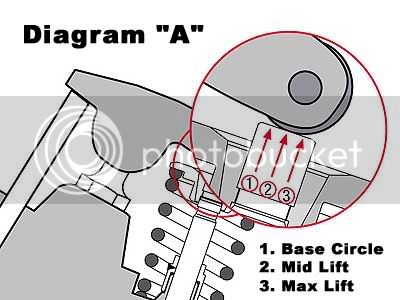

ok on a closed valve you want the rocker tip(bit that you adjust clearance) to be somewhere around number 3 in that pic.

and on full valve opening you want the rocker tip to be at number 1 in the pic...

add a longer valve and the rocker tip will be closer to the middle meaning on full valve lift the rocker tip is going to be close to the edge of the valve....

in a push rod engine this is recified by using longer pushrods, but we have a cam there instead so we cant add anything unless we spray weld it and get it hardened again...lets put that in the too hard basket and overkill...

ok next. if we raise the height of the collet groove then we have to add the raised amount to under the spring to correct the spring tension on the valve seat...

you may be thinking but its only 1mm...1mm is enough to loose 10-20lbs seat pressure...and these engines dont have alot to start with....

also if you raise the collet groove but retain the total valve length then you run the risk of the retainer hitting the rocker...

ok, im starting to sound like a tafe teacher now.....im guessing you get the picture...

keep everything standard length and only change the springs.

if your valves dont look too bad just lap them back in. if there fooked then buy the exact valves that came out of it...

hmmm my head herts...^^^ too much going on i think

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)

![LISEN Bike Phone Holder, [2024 Upgrade] Motorcycle Phone Mount, Bicycle Phone Holder, Handlebar Phone Mount, Dirt Bike Accessories, Bicycle Accessories, Gifts for Men for iPhone 4.7-7" Phone, Black](https://m.media-amazon.com/images/I/41FJGrZQ5ML._SL500_.jpg)