Squeeby

Well-Known Member

- Joined

- Oct 13, 2006

- Messages

- 385

- Reaction score

- 1

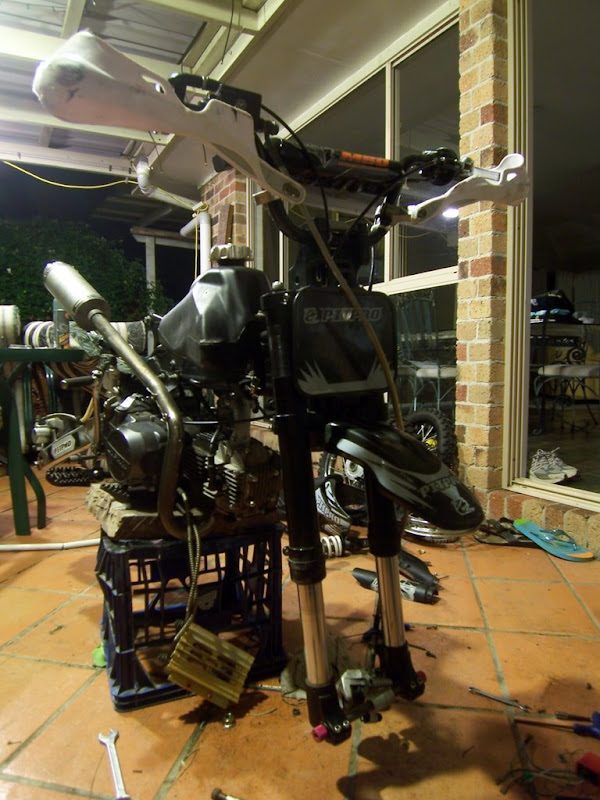

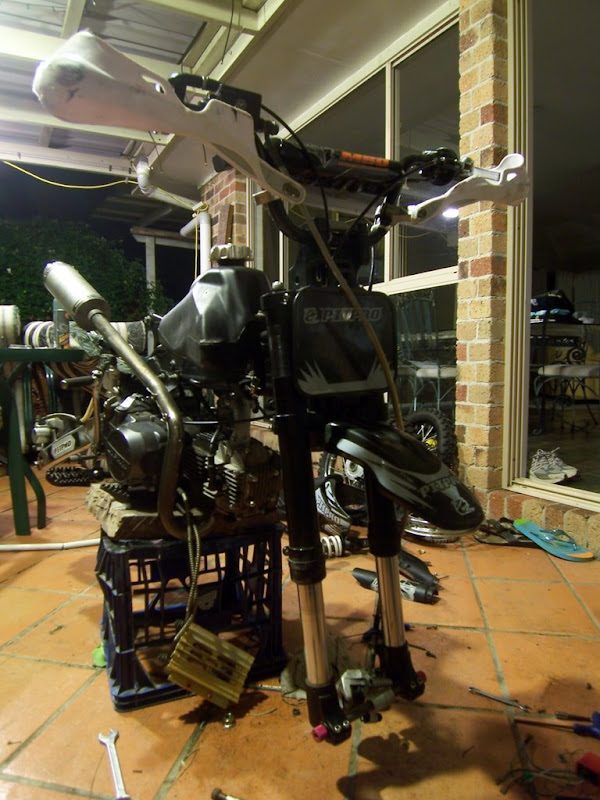

This is Dad's 2006 Pitpro 140 as it stood in mid-2007; everything is the way it came from the factory other than the 12” front wheel and Chinese-made nylon tires. The rear shock has a serious lack of damping, the tyres give very little feedback, the muffler is choking the motor and the brakes are very weak. So now that we've established what the bike was like, let's move on to the modifications.

Adding a lot of preload and ensuring that there was as much air in the shock's gas reservoir did help somewhat, however it simply wasn't up to the job and the same went for the tires. We sourced a second hand Fastace BS-35 and upgraded to Bridgestone B03/B02 rubber. In addition, we purchased some handguards because we were getting tired of replacing crash damaged levers. The air filter had also been torn up from sliding down the road so often and so a new Unifilter was fitted and the jetting was altered slightly. The pegs had also seen better days and so a stronger peg mount was fitted along with beefier pegs. Finally, there was no need for a bash plate so that was removed. You can see the changes in the photo below (except for the rear shock).

For the next 10-12 months progress was minimal due to lack of money being spent on the bike and a series of accidents in which Dad tore his calf muscle and broke an arm. As a result, he took several weeks off work and many months away from the track. Recently, he made the decision to return to track riding and I convinced him to upgrade his ride, particularly the suspension.

I originally intended to simply rebuild the forks using heavier oil but it was later agreed upon that we would change to full DNM suspension to match my bike and thus be on a closer level in terms of machinery between Dad's bike and mine. The first hurdle we ran into was the difference in fork diameter. The standard Chinese USD forks were 42mm at the top triple clamp and 48mm at the bottom clamp whereas the DNM M-200 forks are 48mm top and bottom. To make matters worse, both the 48mm triple clamp sets I had available were 5mm narrower meaning the 110/90 Bridgestone would no longer fit between the fork legs.

You can trim back the rubber a little, but we decided to change the tires for two reasons. Firstly, the 120/70 rear was too wide for the 2.15” rim we had on the back, and secondly, Dad was the only one left running on scooter tires front and rear at the track; it was time for race rubber! Sava, Innova, Dunlop, Vee Rubber and Bridgestone are the main manufacturers of 12” race tires. Unfortunately, Bridgestone don't seem to make their famous BT601 anymore and I couldn't get a hold of the Savas or Innovas. That left me with a choice between Dunlop TT92 and Vee Rubber VRM266 slicks. After reading pages and pages of feedback and reports comparing the two I concluded that the Vee Rubber offers better grip but comes apart much quicker while the Dunlops were also a very good tire but was more focussed on durability. It seems to be a matter of opinion as to which is actually the better tire; both were priced similarly and a few guys at the track were already running Dunlop so we thought we'd try something new.

But back to the forks for a moment. The steering stem was about a centimetre too long. Fortunately, wheel bearing dust caps were just the right size and two of them bridged the gap. The other problem was the stock brake caliper mounting points were just a millimetre or two too narrow. I could either grind the bolt holes on the forks out a little or upgrade the caliper on my bike and donate my stock one to Dad. Guess which I went for? I also donated my handlebars to Dad as his were rather bent up and also had a fair bit of flex to them. I then began to focus on the engine while I waited for additional parts in the mail.

In the two years that we've owned the Pitpro the valve clearances had never been checked. I did a bit of research on how to do it then went out and bought a set of feeler gauges. Little while later the valves were done and the engine ran much smoother (it previously had a bit of a problem idling) and was much more responsive. Here's hoping the two years of neglect hadn't caused any damage.

I had changed the carburettor on my bike to a Mikuni VM24 and so I donated my Mikuni “25mm” to Dad to replace his “30mm”. Initially I forgot to change the gaskets over and so it was blocking a considerable amount of flow but that was later rectified. Out of curiousity I also pulled off the intake manifold and was surprised to find a rather large obstruction. The manifold was replaced immediately. Now that the intake had been improved, I put on a less restrictive muffler. I suppose it was basically an 'aftermarket slip-on' hehe.

Thanks for reading so far, more to come in the next few days!

Adding a lot of preload and ensuring that there was as much air in the shock's gas reservoir did help somewhat, however it simply wasn't up to the job and the same went for the tires. We sourced a second hand Fastace BS-35 and upgraded to Bridgestone B03/B02 rubber. In addition, we purchased some handguards because we were getting tired of replacing crash damaged levers. The air filter had also been torn up from sliding down the road so often and so a new Unifilter was fitted and the jetting was altered slightly. The pegs had also seen better days and so a stronger peg mount was fitted along with beefier pegs. Finally, there was no need for a bash plate so that was removed. You can see the changes in the photo below (except for the rear shock).

For the next 10-12 months progress was minimal due to lack of money being spent on the bike and a series of accidents in which Dad tore his calf muscle and broke an arm. As a result, he took several weeks off work and many months away from the track. Recently, he made the decision to return to track riding and I convinced him to upgrade his ride, particularly the suspension.

I originally intended to simply rebuild the forks using heavier oil but it was later agreed upon that we would change to full DNM suspension to match my bike and thus be on a closer level in terms of machinery between Dad's bike and mine. The first hurdle we ran into was the difference in fork diameter. The standard Chinese USD forks were 42mm at the top triple clamp and 48mm at the bottom clamp whereas the DNM M-200 forks are 48mm top and bottom. To make matters worse, both the 48mm triple clamp sets I had available were 5mm narrower meaning the 110/90 Bridgestone would no longer fit between the fork legs.

You can trim back the rubber a little, but we decided to change the tires for two reasons. Firstly, the 120/70 rear was too wide for the 2.15” rim we had on the back, and secondly, Dad was the only one left running on scooter tires front and rear at the track; it was time for race rubber! Sava, Innova, Dunlop, Vee Rubber and Bridgestone are the main manufacturers of 12” race tires. Unfortunately, Bridgestone don't seem to make their famous BT601 anymore and I couldn't get a hold of the Savas or Innovas. That left me with a choice between Dunlop TT92 and Vee Rubber VRM266 slicks. After reading pages and pages of feedback and reports comparing the two I concluded that the Vee Rubber offers better grip but comes apart much quicker while the Dunlops were also a very good tire but was more focussed on durability. It seems to be a matter of opinion as to which is actually the better tire; both were priced similarly and a few guys at the track were already running Dunlop so we thought we'd try something new.

But back to the forks for a moment. The steering stem was about a centimetre too long. Fortunately, wheel bearing dust caps were just the right size and two of them bridged the gap. The other problem was the stock brake caliper mounting points were just a millimetre or two too narrow. I could either grind the bolt holes on the forks out a little or upgrade the caliper on my bike and donate my stock one to Dad. Guess which I went for? I also donated my handlebars to Dad as his were rather bent up and also had a fair bit of flex to them. I then began to focus on the engine while I waited for additional parts in the mail.

In the two years that we've owned the Pitpro the valve clearances had never been checked. I did a bit of research on how to do it then went out and bought a set of feeler gauges. Little while later the valves were done and the engine ran much smoother (it previously had a bit of a problem idling) and was much more responsive. Here's hoping the two years of neglect hadn't caused any damage.

I had changed the carburettor on my bike to a Mikuni VM24 and so I donated my Mikuni “25mm” to Dad to replace his “30mm”. Initially I forgot to change the gaskets over and so it was blocking a considerable amount of flow but that was later rectified. Out of curiousity I also pulled off the intake manifold and was surprised to find a rather large obstruction. The manifold was replaced immediately. Now that the intake had been improved, I put on a less restrictive muffler. I suppose it was basically an 'aftermarket slip-on' hehe.

Thanks for reading so far, more to come in the next few days!

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)

![2 Pack Bike Phone Holder Mount [2024 Upgraded Gift Set]- 3S Easy Install, Motorcycle Phone Mount Universal Handlebar, Cell Phone Holder Fit for EBikes Electric Scooter Dirt, Bike Accessories for Adult](https://m.media-amazon.com/images/I/41JK0xwDupL._SL500_.jpg)