epod

Well-Known Member

- Joined

- Oct 26, 2006

- Messages

- 222

- Reaction score

- 3

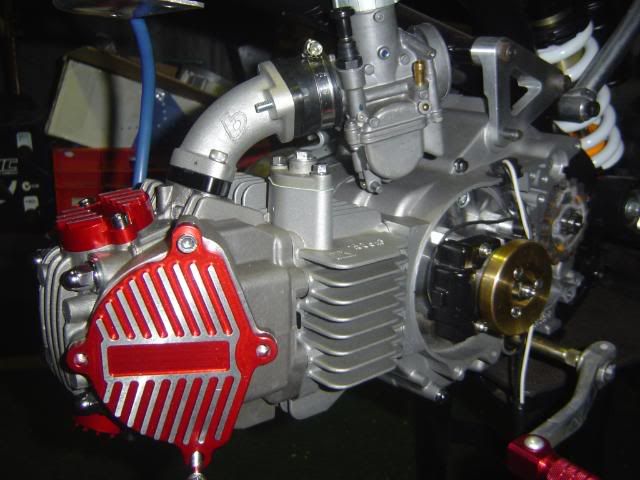

Hey bro's I thought tech talk is a bit stale lately so I thought I try to find out what some of you guys are doinging with you YX motors. I know of all the options out there but my 150 and 160 are still stock and running great after 12 months flogging riding. I have replaced the clutch and stator in my 160 during that time and no issues with the 150. They have both done about 35 to 40 hours over twelve months. I cant wait to work one of my 2 mootors though, I have a 7.2mm akunar cam to go in but I figure I will wait until 1 is due for a piston and rings and then do the works, new clutch, cam, high comp piston, bore out barrel probably my 160 pitster up to 184cc

So id like to know who is on big bore bikes like 172cc 184cc or even 192cc. Whats you set up, did you build it yourself. Has anybody used a stock barrel bored out or resleevd. Do you use a stock or ported head. Is anybody running six plates in stock clutch basket. How much fun are they compared to the stock motor and have you had any reliability issues before or after 15hours of riding. Also What gearing are you guys running.

Ride on.

So id like to know who is on big bore bikes like 172cc 184cc or even 192cc. Whats you set up, did you build it yourself. Has anybody used a stock barrel bored out or resleevd. Do you use a stock or ported head. Is anybody running six plates in stock clutch basket. How much fun are they compared to the stock motor and have you had any reliability issues before or after 15hours of riding. Also What gearing are you guys running.

Ride on.

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)

![LISEN Bike Phone Holder, [2024 Upgrade] Motorcycle Phone Mount, Bicycle Phone Holder, Handlebar Phone Mount, for iPhone Bike Mount, Bike Accessories, Bicycle Accessories for iPhone 4.7-7"Phone, Black](https://m.media-amazon.com/images/I/41FJGrZQ5ML._SL500_.jpg)