storminnorman07

Well-Known Member

- Joined

- Jan 10, 2007

- Messages

- 159

- Reaction score

- 5

the cases i modded for this klx top end where not the best of cases. i was antsy and my pantsy after the first set of cases i did i didnt really look this set over well to make sure they where good. well that end up biting me in the arse. first it was the cases was all pitted and look like hell, then after doing all the welding and machinng for the new stud pattern i found the shift shaft hole in the cases was oblonged so it was either do another set of cases of bush it since there is a bunch of time welding and machining bushing it was what i opted for but have been putting it off for weeks cause 1 cheapest i found brass is about 50 us shipped for a lil 6 inch piece 2 being the holes are so oblonged it is darn near impossible to find a true center. so i moved on to tumbling and polishing the tranny which i found was JUNK i wouldn't even run that in a stocker for a trail beater. that was the last straw that broke the camels back i whipped the rack acrossed the garage through all my chit in a box and kiced under the bench. however i got a spurt of motivation tonight and started tackling some of the to do list to wrap this motor up. i first dove in on that shift shaft bushing figuring if it goes wrong i can start over again without being further involved in these cases. i successfully put the bushings in and got a nice .0015 inch interferance. i then jumped to the timing chain slide that bolts to the case. found center, drilled, spot faced and tapped. i then jumped to putting holes in the xr 80 cam gear to work with the yx cam. i still have not purchased a rotary table for my mill so i figured i could mic, math and indicate everythign out. well i was a little off its about 1/4 to 1/2 tooth off time. oh well looks like i'll have to get my arse in gear on picking up a table so i can slot it and get timing right. then again i could always fudge the lower sprocket on the crank a lil.

now the to do list goes like this. the gdfp is sending me a good tranny so once i get that in hand it will spend a few days tumbling then will get some refined hand polshing. make the bushings for bottom of the timing chain slide so its not sloppy, the other time chain slide that slides into the cylinder has to be morphed the bottom half that goes in the cases will be the xr slide the portion that slides in the cylinder will be klx i have one cut just have to figure length and put it together, the intake needs a couple spots of weld so i can mill flat and put holes to accept the carb boot right to the head, order a takegawa clutch and mag cover, then dry assemble clay the head check clearances prolly will have to fly cut the piston with this other cam i picked up clean up and assemble and motors done.

here are some progress pics for ya'll to enjoy

bushing for shift shaft

bushing for shift shaft

another view of shift shaft bushing

another view of shift shaft bushing

pilot hole for timing chain slide

pilot hole for timing chain slide

hole tapped spot face and tightend for slide

hole tapped spot face and tightend for slide

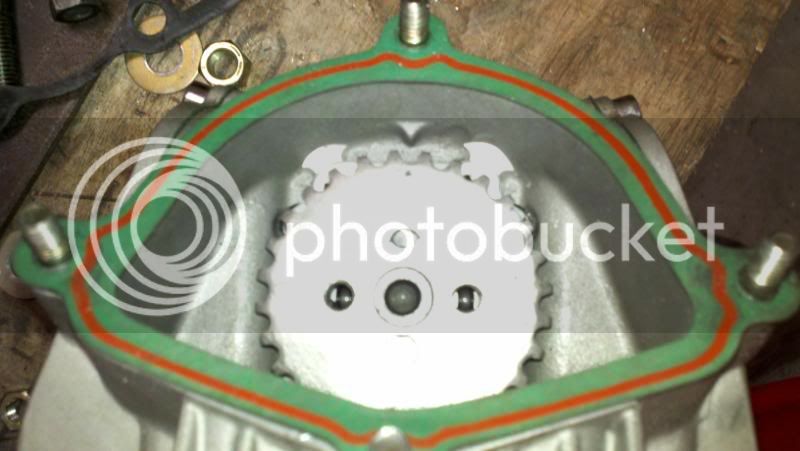

panned out view to show slide in cases

panned out view to show slide in cases

now the to do list goes like this. the gdfp is sending me a good tranny so once i get that in hand it will spend a few days tumbling then will get some refined hand polshing. make the bushings for bottom of the timing chain slide so its not sloppy, the other time chain slide that slides into the cylinder has to be morphed the bottom half that goes in the cases will be the xr slide the portion that slides in the cylinder will be klx i have one cut just have to figure length and put it together, the intake needs a couple spots of weld so i can mill flat and put holes to accept the carb boot right to the head, order a takegawa clutch and mag cover, then dry assemble clay the head check clearances prolly will have to fly cut the piston with this other cam i picked up clean up and assemble and motors done.

here are some progress pics for ya'll to enjoy

![LISEN Bike Phone Holder, [2024 Upgrade] Motorcycle Phone Mount, Bicycle Phone Holder, Handlebar Phone Mount, Dirt Bike Accessories, Bicycle Accessories, Gifts for Men for iPhone 4.7-7" Phone, Black](https://m.media-amazon.com/images/I/41FJGrZQ5ML._SL500_.jpg)

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)