i fitted up the Daytona style Adjustable Outer Rotor kit onto the Ho the other night.

i noticed that the wiring on the back of the stator rubbed across the sharp edges of the backing plate

i thought i'd fix this problem by grinding/filing it back a bit to give it more clearance

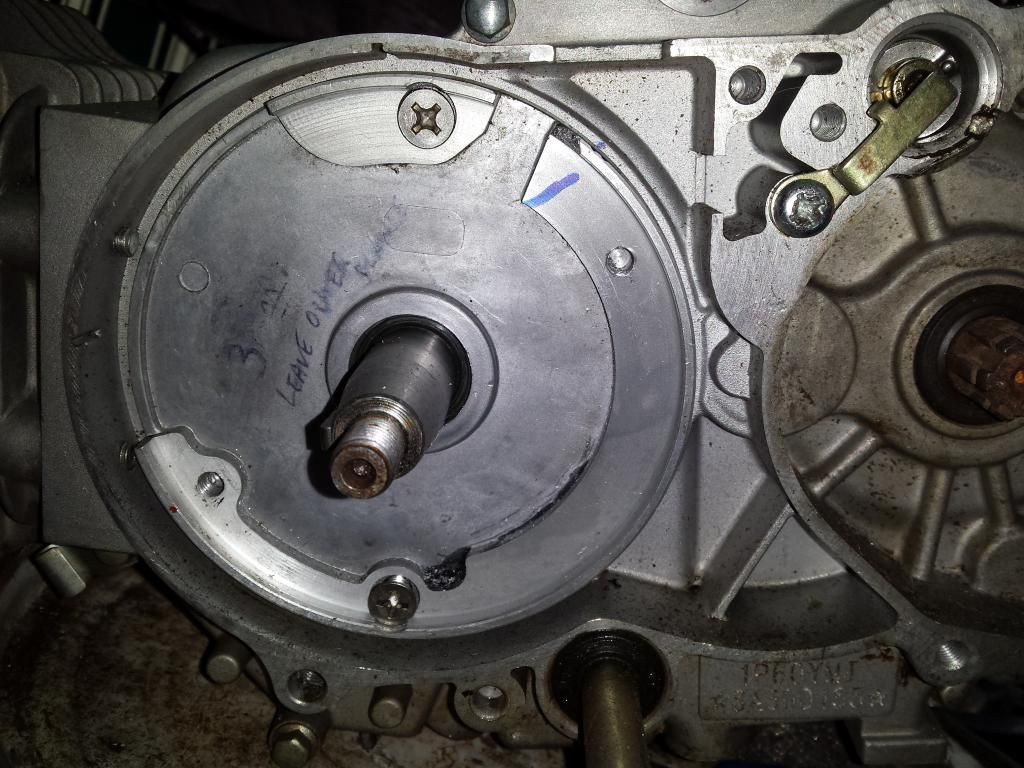

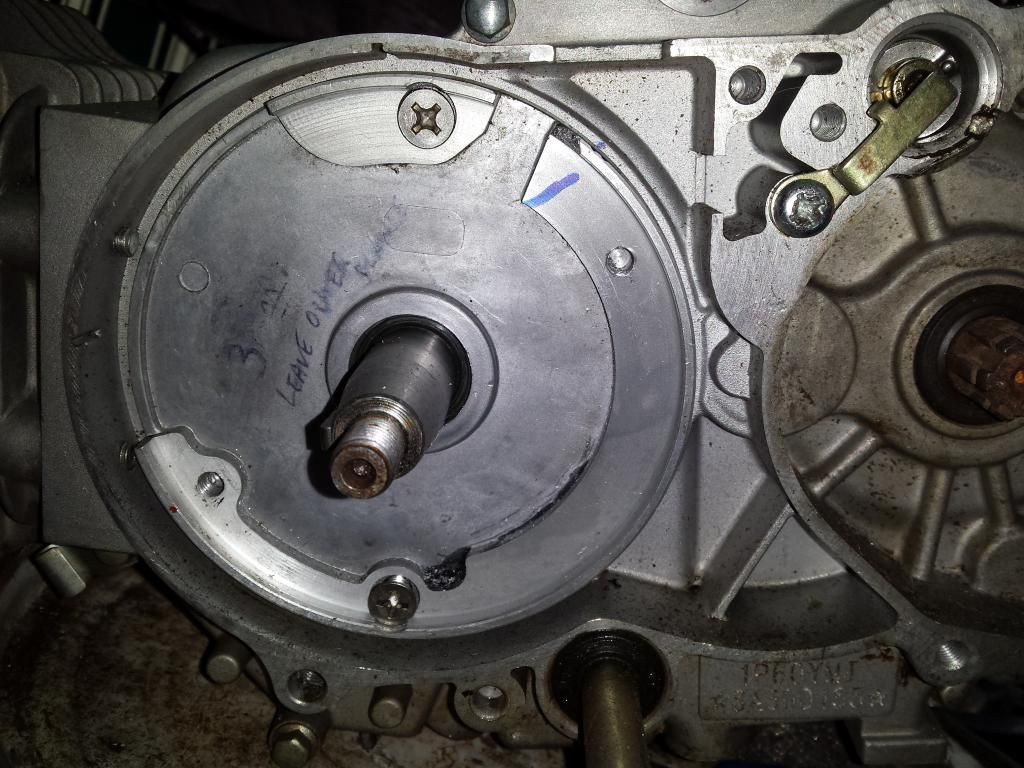

this pic shows the modified backing plate fitted to the engine, you can see where the stator plate bolts to that its been machined 3mm deeper to give the flywheel some clearance

the section marked in blue needs to be trimmed back to stop the wiring insulation from rubbing through.

if you look just above it to the right you can see where the wiring runs in the casings' cutout

thought it would be worth doing to same me future hassles

here's a pic showing a standard backing plate against the 3mm machined one

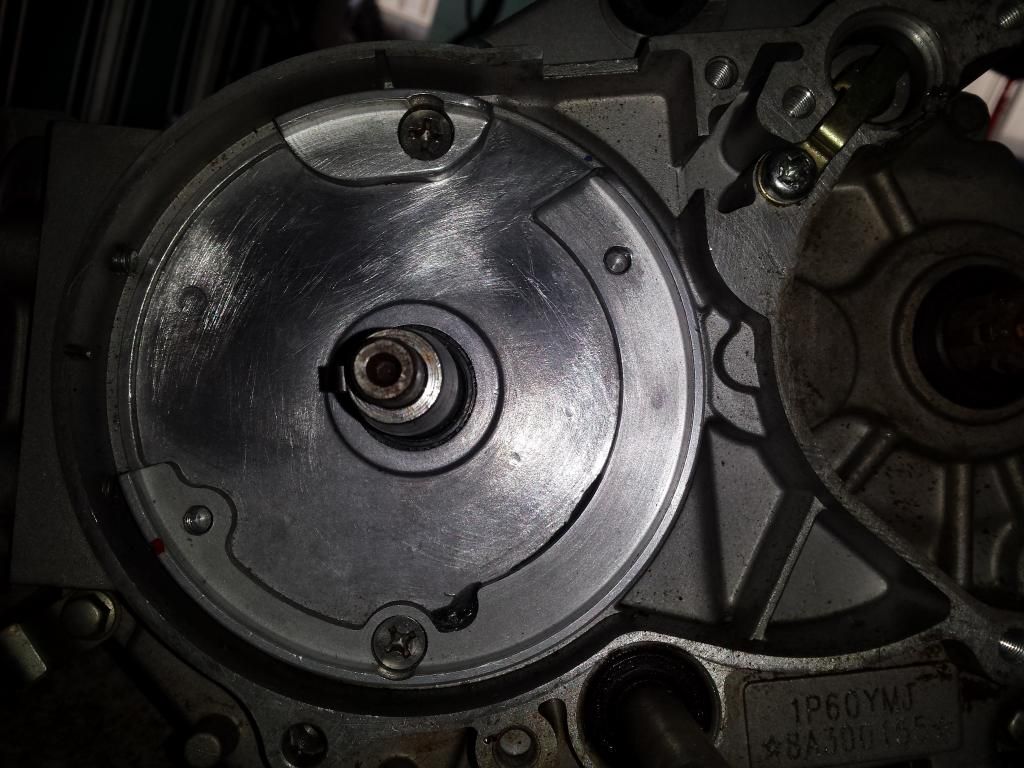

and here is the modified cutaway section, it's sitting on top of another machined backing plate (stoozo's)

the wiring slot is now 10mm wider, and all the edges have been rounded

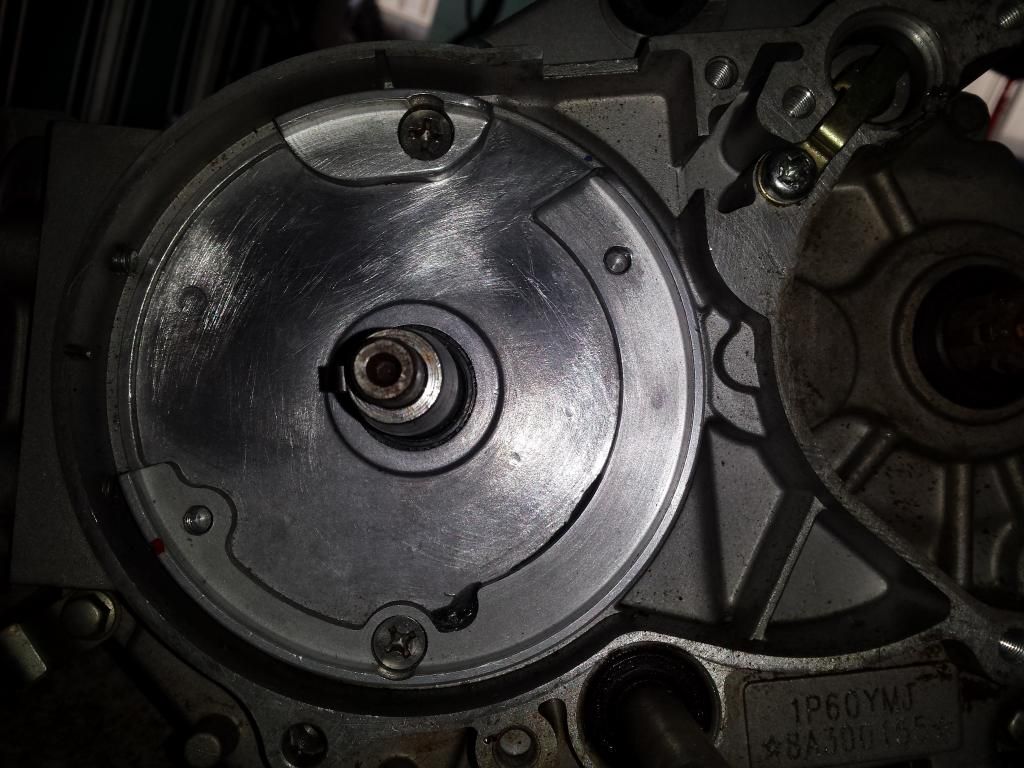

and here it is fitted, i bought some new backing plate mounting screws too, they are M6 x 16mm countersunk 316 Stainless

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)

![LISEN Bike Phone Holder, [2024 Upgrade] Motorcycle Phone Mount, Bicycle Phone Holder, Handlebar Phone Mount, for iPhone Bike Mount, Bike Accessories, Bicycle Accessories for iPhone 4.7-7"Phone, Black](https://m.media-amazon.com/images/I/41FJGrZQ5ML._SL500_.jpg)