Any good port in a storm

I would just like to say that this is a great thread and it has inspired me to have a crack and port both my 140cc lifan and 119cc jialing (or jialing copy) heads.

the 140 head is still sitting om the bench half finished, but I have finaly got my 119cc head back from the machinist. It now has a big valve setup with the 27mm intake (turned down about 1mm to clear exhaust valve) and 23mm exhaust from the 140 now fitted, custom seats and multi-angle grinds. I tried to get it all done as cheap as possible and told to them not to rush, so it did take a little while to get it back in the end. But it only cost me about $135 to get it all done (best money I have spent yet!)

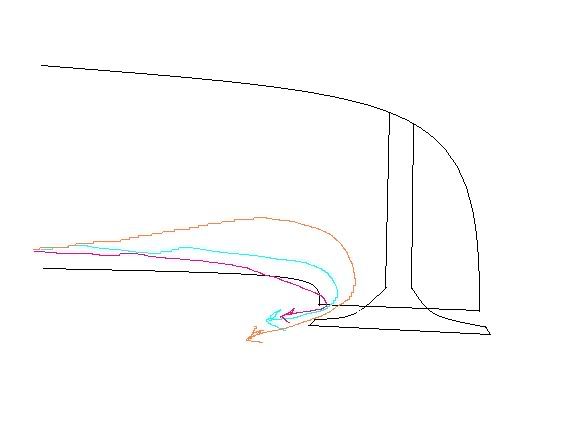

Anyway here is a couple of pics of the intake port, I used epoxy to build up the short side radius, to help create a better angle for air to flow to that part of the vale and seat and also create a higher velocity for the airflow at the same time. Also I had to use some more z-spar to patch up and give some support to the spot where I broke through into the valve spring seat area, but it was very easy to fix, I have just used the original valve seat spring washer (didn't cost me anything extra) and all seems to going be well so far.

This is only my second go at porting, the first attempt was not very pretty to say the least and the head still bears a few battle scars from original my hack job (so please don't laugh to hard at my latest attempt). Mack I am very keen to get some feedback so I know what to do differently for the 140. Also I though the pics might help Tubes or any body else considering this mod, help get an idea of what to do..... or not to do when it comes to building up the short side radius etc.

The pics are a bit grainy,had to much around with photoshop as they were pitch black inside..... Oh well enjoy;

EDIT: I now realise how stupid it was puttting up these porting posts and pics... I did not try to stuff anyone around or anything like that, or know how much trouble it would cause... I am so very sorry for my actions ( I spent frigging ages trying to get the ports etc. right and did not think it through properly, or realise how secrectative it all is) and have now removed them...

![LISEN Bike Phone Holder, [2024 Upgrade] Motorcycle Phone Mount, Bicycle Phone Holder, Handlebar Phone Mount, Dirt Bike Accessories, Bicycle Accessories, Gifts for Men for iPhone 4.7-7" Phone, Black](https://m.media-amazon.com/images/I/41FJGrZQ5ML._SL500_.jpg)

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)