my67xr

Miniriders Legend and Master Spanner Spinning Mode

Sound's like either there's something stuck in the needle and seat, and that's not letting it close properly, or the centre tab on the brass float arm might be bent?

Have you replaced the fuel hose ?

Old hose can get brittle and a small piece may have come off and be stuck in the carbys' needle and seat.

If the needle and seat is clean, then the tang on the float arm may be bent

Take the carby off then the fuel bowl off,

Hold the carby upright and check that when the float is lifted so the float arm centre tab is just touching the pin in the bottom of the needle, the bottom of the float should be about 25mm off the fuel bowl mounting face (bottom of carby)

You can even connect up the fuel hose and turn the tap on, check that when you lift the float that the float arm is parrallel to the base of the carby and the fuel should stop running out the bottom of the needle and seat.

If the float need's to be raised more to shut off the fuel then the centre tab need's to be carefully bent up a little

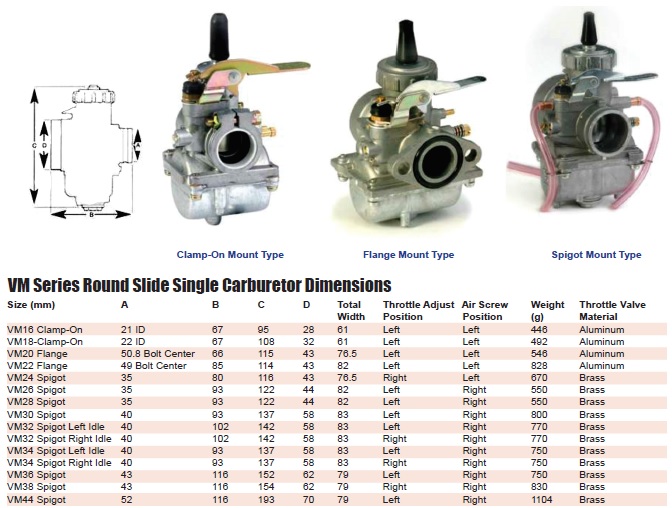

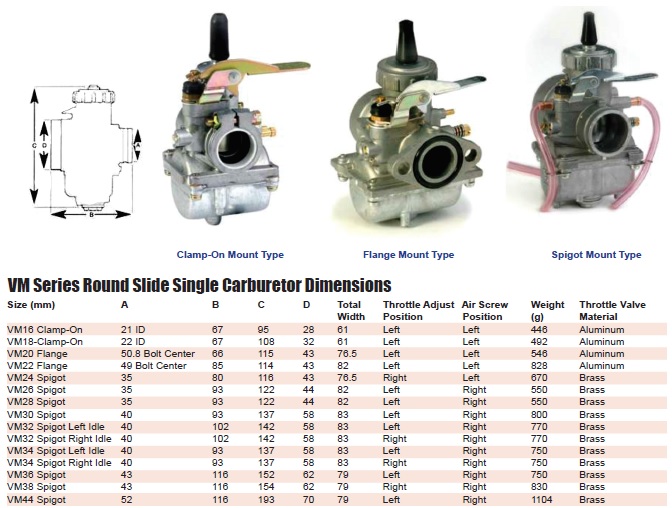

Your carby is a Mikuni VM22, the dimension are down below in the pic

Standard jetting is a #25 Pilot jet, and #87.5 main jet

Suzuki Motorcycle Parts 1996 DS80 CARBURETOR Diagram

Have you replaced the fuel hose ?

Old hose can get brittle and a small piece may have come off and be stuck in the carbys' needle and seat.

If the needle and seat is clean, then the tang on the float arm may be bent

Take the carby off then the fuel bowl off,

Hold the carby upright and check that when the float is lifted so the float arm centre tab is just touching the pin in the bottom of the needle, the bottom of the float should be about 25mm off the fuel bowl mounting face (bottom of carby)

You can even connect up the fuel hose and turn the tap on, check that when you lift the float that the float arm is parrallel to the base of the carby and the fuel should stop running out the bottom of the needle and seat.

If the float need's to be raised more to shut off the fuel then the centre tab need's to be carefully bent up a little

Your carby is a Mikuni VM22, the dimension are down below in the pic

Standard jetting is a #25 Pilot jet, and #87.5 main jet

Suzuki Motorcycle Parts 1996 DS80 CARBURETOR Diagram

Last edited:

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)

![LISEN Bike Phone Holder, [2024 Upgrade] Motorcycle Phone Mount, Bicycle Phone Holder, Handlebar Phone Mount, Dirt Bike Accessories, Bicycle Accessories, Gifts for Men for iPhone 4.7-7" Phone, Black](https://m.media-amazon.com/images/I/41FJGrZQ5ML._SL500_.jpg)

![2 Pack Bike Phone Holder Mount [2024 Upgraded Gift Set]- 3S Easy Install, Motorcycle Phone Mount Universal Handlebar, Cell Phone Holder Fit for EBikes Electric Scooter Dirt, Bike Accessories for Adult](https://m.media-amazon.com/images/I/41ofXpnkkZL._SL500_.jpg)