The_GDFP

Master Spanner Spinner

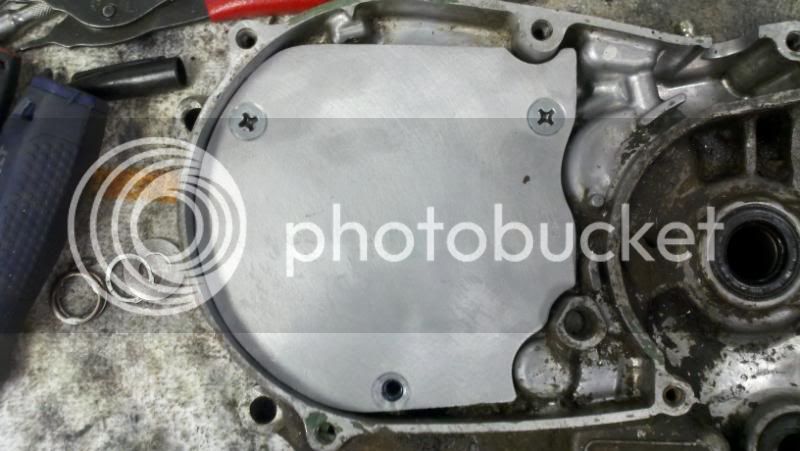

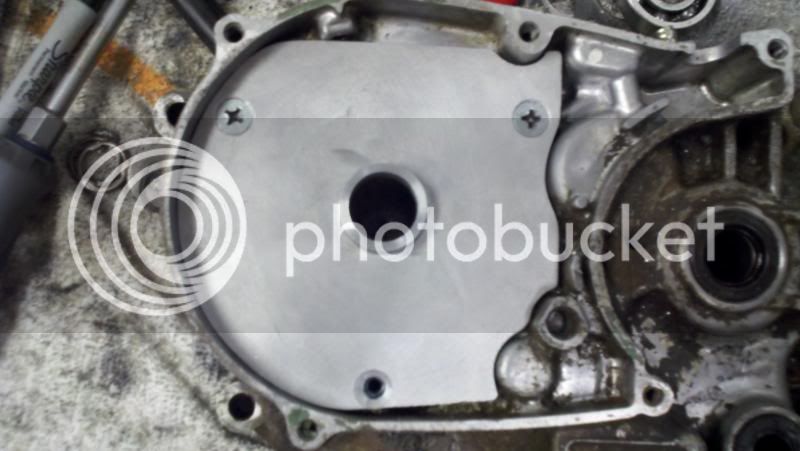

Is Jake's faster than your brother's? +R vs S3 head was the only difference, besides ignition? Did you write down the recipe for the backing plate?

Is Jake's faster than your brother's? +R vs S3 head was the only difference, besides ignition? Did you write down the recipe for the backing plate?

copy that....my sl12o build need something like thatExcellent work ! I'd say you'd sell a few of those stator backing plates to the XR crowd ...

who is the 1 who makes them plates?.how much would u sell 1 for?

copy that....my sl12o build need something like that

:beerchug:

not exactly ...but thanks for the link:thumbup::beerchug:Molehill, you have a 100/125-type engine, don't you? Apples & Aardvarks. Use a CB100 inner-rotor, that incorporates a lighting coil. Trick as.

On the Problem of the Honda XR200

Awesome job on the proof-of-concept run. Sounds like you're on to some thing:thumbup:

Tumbling Media, Deburring Media, Ceramic Media, Plastic Media, Vibratory Media

There look to be some easier options than hammering the big triangles in to small ones.

Silicon carbide, maybe?

Probably have an extra shaft or two, if you haven't got back-up's.

I may have a solution or two. PM'ed one on MMU. The other is buy:

Cnc mill

I'm sure there would be ways to make it pay off

Ah, Chad, you're an easy one to lead astrayKidding. Ish...lol

I did a fair bit of searching and inquiring when I was looking at the Deepgroove. Seems pretty easy to program. The software is basic. Not sure it's got the arse for gear-cutting, but triples would work. It would take a lot more passes than a retro-d 2HP Bridgeport, but you said space is tight, and 3-phase 440v isn't in every one's garage. Over a ton of iron, too. My dad was going to help program mine, if I'd ought one. Retired GM machinist, so he makes pretty good coffee, and can toss chips ok too. Slimbo on the planet, John Lyter on my FB, does a lot of small-scale work and pointed me to that unit.

Enter your email address to join: