bulldog93

Well-Known Member

Okay I've been searching and learning about honing. I've had a look at a few web-sites and vids and this is what I've came up with.

Honing is a final finishing operation conducted on a surface, typically of an inside cylinder, such as of an automotive engine block. Abrasive stones are used to remove minute amounts of material in order to tighten the tolerance on cylindricity. Honing is a surface finish operation, not a gross geometry-modifying operation. Hones can be of the multiple pedal type (pictured below) or the brush type. Either type applies a slight, uniform pressure to a light abrasive that wipes over the entire surface.

The figure below illustrates the configuration of the abrasive stones of an external hone.

Below are illustrated bad and good honed part geometries. Both pairs of figures show that a through hole design is always best for coolant flow, etc. The upper pair shows that a certain portion at the end of a blind hole is not completely honed. The lower pair shows that a right circular cylinder is the easiest to hone.

A hone is a machine tool used in the manufacture of precision bores to improve the geometry, surface finish and dimensional control of the finished part. This process is called honing.

Typical applications are the finishing of cylinders for internal combustion engines, air bearing spindles and in gear manufacturing. Types of hone are many and various but all consist of one or more abrasive stones that are held under pressure against the surface they are working on.

The hone is usually turned in the bore while being moved in and out. Special cutting fluids are used to give a smooth cutting action and to remove the material that has been abraded. Machines can be portable, simple manual machines, or fully automatic with gauging depending on the application.

Modern advances in abrasives have made it possible to remove much larger amount of material than was previously possible. This has displaced grinding in many applications where "through machining" is possible. External hones perform the same function on shafts.

Cross-hatch finish

A "cross-hatch" pattern is used to retain oil or grease to ensure proper lubrication and ring seal of pistons in cylinders. A smooth glazed cylinder wall can cause piston ring and cylinder scuffing. The "cross-hatch" pattern is used on brake rotors, and flywheels.

Plateau finish

A tool with the brand name Flex-Hone made by Brush Research Manufacturing Co., Inc. was introduced as a hone with many of the benefits of honing without the need for labor intensive set up or training. The tool is often referred to as a "ball-hone" for its many abrasive globules mounted to the ends of flexible nylon filament. The result of using this tool is that it provides a cross hatched finish while achieving a plateau finish at the same time.

The Plateau Finish is one characterized by the removal of "peaks" in the metal while leaving the cross hatch intact for oil retention. The plateaued finish increases the bearing area of the finish, and does not require the piston or ring to "break in" the cylinder walls.

Other similar processes are lapping and superfinishing.

A few VIDS:

YouTube - H-D Cylinder Honing

YouTube - How To Use a Flex-Hone Tool

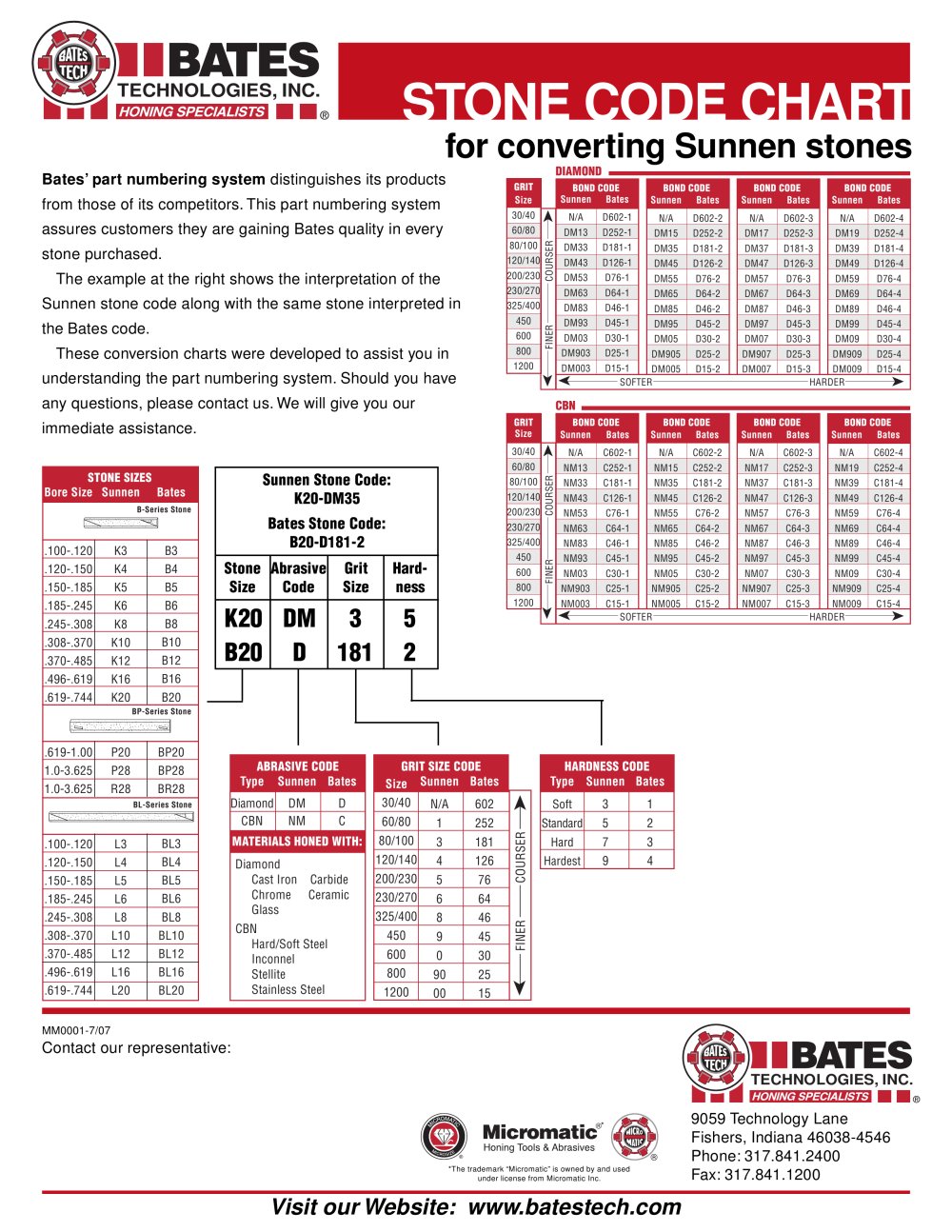

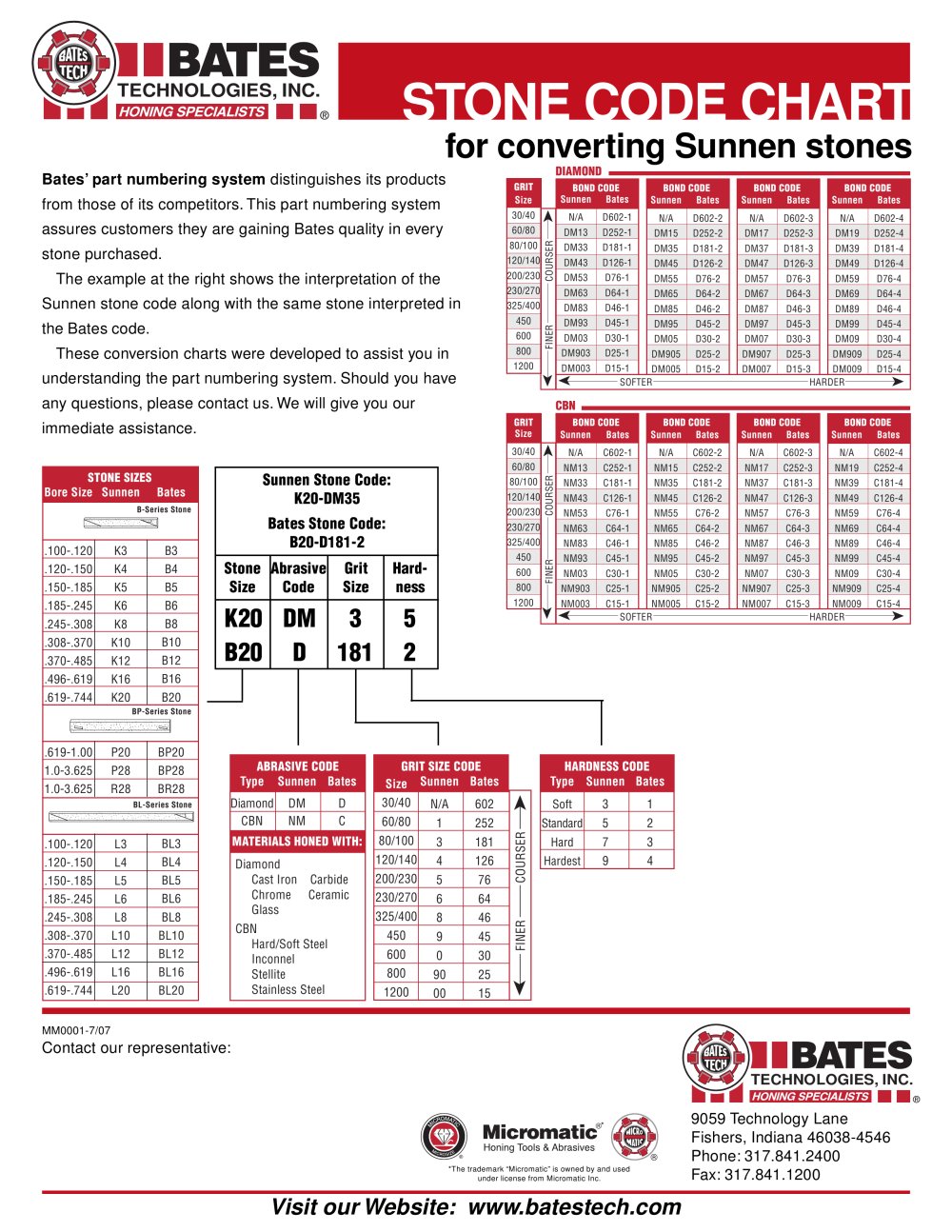

I'm still trying to find more info on the honing stones. If you have an info regarding honing please post. Also after more vids.

Honing is a final finishing operation conducted on a surface, typically of an inside cylinder, such as of an automotive engine block. Abrasive stones are used to remove minute amounts of material in order to tighten the tolerance on cylindricity. Honing is a surface finish operation, not a gross geometry-modifying operation. Hones can be of the multiple pedal type (pictured below) or the brush type. Either type applies a slight, uniform pressure to a light abrasive that wipes over the entire surface.

The figure below illustrates the configuration of the abrasive stones of an external hone.

Below are illustrated bad and good honed part geometries. Both pairs of figures show that a through hole design is always best for coolant flow, etc. The upper pair shows that a certain portion at the end of a blind hole is not completely honed. The lower pair shows that a right circular cylinder is the easiest to hone.

A hone is a machine tool used in the manufacture of precision bores to improve the geometry, surface finish and dimensional control of the finished part. This process is called honing.

Typical applications are the finishing of cylinders for internal combustion engines, air bearing spindles and in gear manufacturing. Types of hone are many and various but all consist of one or more abrasive stones that are held under pressure against the surface they are working on.

The hone is usually turned in the bore while being moved in and out. Special cutting fluids are used to give a smooth cutting action and to remove the material that has been abraded. Machines can be portable, simple manual machines, or fully automatic with gauging depending on the application.

Modern advances in abrasives have made it possible to remove much larger amount of material than was previously possible. This has displaced grinding in many applications where "through machining" is possible. External hones perform the same function on shafts.

Cross-hatch finish

A "cross-hatch" pattern is used to retain oil or grease to ensure proper lubrication and ring seal of pistons in cylinders. A smooth glazed cylinder wall can cause piston ring and cylinder scuffing. The "cross-hatch" pattern is used on brake rotors, and flywheels.

Plateau finish

A tool with the brand name Flex-Hone made by Brush Research Manufacturing Co., Inc. was introduced as a hone with many of the benefits of honing without the need for labor intensive set up or training. The tool is often referred to as a "ball-hone" for its many abrasive globules mounted to the ends of flexible nylon filament. The result of using this tool is that it provides a cross hatched finish while achieving a plateau finish at the same time.

The Plateau Finish is one characterized by the removal of "peaks" in the metal while leaving the cross hatch intact for oil retention. The plateaued finish increases the bearing area of the finish, and does not require the piston or ring to "break in" the cylinder walls.

Other similar processes are lapping and superfinishing.

A few VIDS:

YouTube - H-D Cylinder Honing

YouTube - How To Use a Flex-Hone Tool

I'm still trying to find more info on the honing stones. If you have an info regarding honing please post. Also after more vids.

Last edited:

![Zewdov Motorcycle Phone Mount, Upgrade Bike Phone Mount [1s Lock][Secure Protection], 360° Rotatable Phone Holder for Mountain Bike/ATV/Scooter Handlebar, Compatible with iPhone/Samsung 4.7-6.7"](https://m.media-amazon.com/images/I/51lvX8e2C3L._SL500_.jpg)

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)

![JOYROOM Bike Phone Holder Mount, [Anti Vibration] Bicycle Phone Mount, Dirt Bike Accessories for All 4.7-7.0" Phones, Motorcycle Phone Mount for iPhone 16 Pro Max/15/14/13/12 Samsung S25 Ultra/S24/S23](https://m.media-amazon.com/images/I/41MPtPvknUL._SL500_.jpg)

![LISEN Bike Phone Holder, [2025 Upgrade] Motorcycle Phone Mount, Bicycle Phone Holder, Handlebar Phone Mount, Dirt Bike Accessories, Bicycle Accessories, for iPhone Samsung Google Pixel, Black](https://m.media-amazon.com/images/I/41FJGrZQ5ML._SL500_.jpg)