You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mikkh's WPB 125 CRF 70 framed build

- Thread starter mikkh

- Start date

Help Support Mini Dirt Bikes & Pit Bikes Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Basically gave up to myself and used good old angle grinder to make the rear shock fit. Well the shock feels soft, but I´ll see it for sure when I test it. Luckily the china springs fit the R6 shock, but my china shock spring shrinked in length with use (about 1cm from stock length, it went progressive I suppose  ).

).

Basically just the brakes and handlebar mounts to do and It will ride hopefully (can´t get to neutral, but it might wear to place because I welded those shift forks).

Planning to rebuild the rear shock just to be sure, but I don´t have nitrogen needle at hand. Thinking of using just a regular needle to unpressurize the rear shock. After that I am thinking of converting it to schrader valve (I have inserts available with M8 X1.00 thread, it looked like that, but I am not exactly sure, it could be imperial thread).

Basically just the brakes and handlebar mounts to do and It will ride hopefully (can´t get to neutral, but it might wear to place because I welded those shift forks).

Planning to rebuild the rear shock just to be sure, but I don´t have nitrogen needle at hand. Thinking of using just a regular needle to unpressurize the rear shock. After that I am thinking of converting it to schrader valve (I have inserts available with M8 X1.00 thread, it looked like that, but I am not exactly sure, it could be imperial thread).

The lifan 120 gearbox is totally trashed  and the front rim is bent because of big jumps, the bike seems to be holding up somehow

and the front rim is bent because of big jumps, the bike seems to be holding up somehow  . If all goes well I will get my yx140 engine tomorrow and take some pictures of the bike and repair the lifan 120 gearbox to use the engine in a go kart. My lifan 150 engine is still in search of crankshaft, cylinder, countershaft needle bearing.

. If all goes well I will get my yx140 engine tomorrow and take some pictures of the bike and repair the lifan 120 gearbox to use the engine in a go kart. My lifan 150 engine is still in search of crankshaft, cylinder, countershaft needle bearing.

The subframe broke down and I decided to brace it. The dark line is just burned paint.

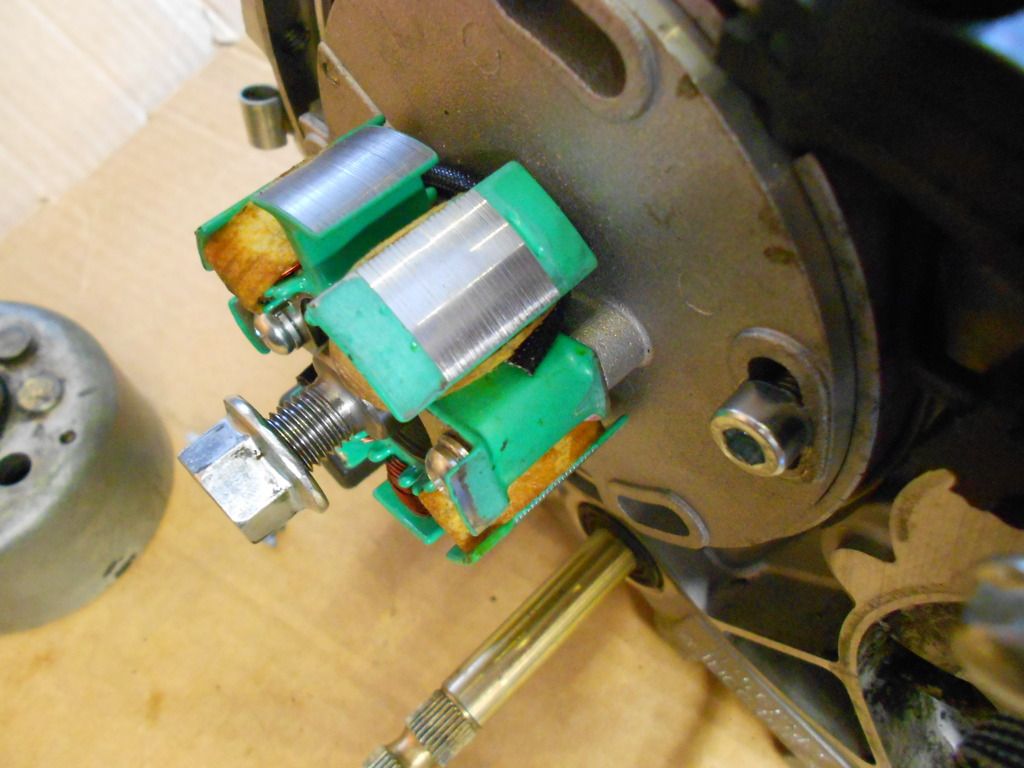

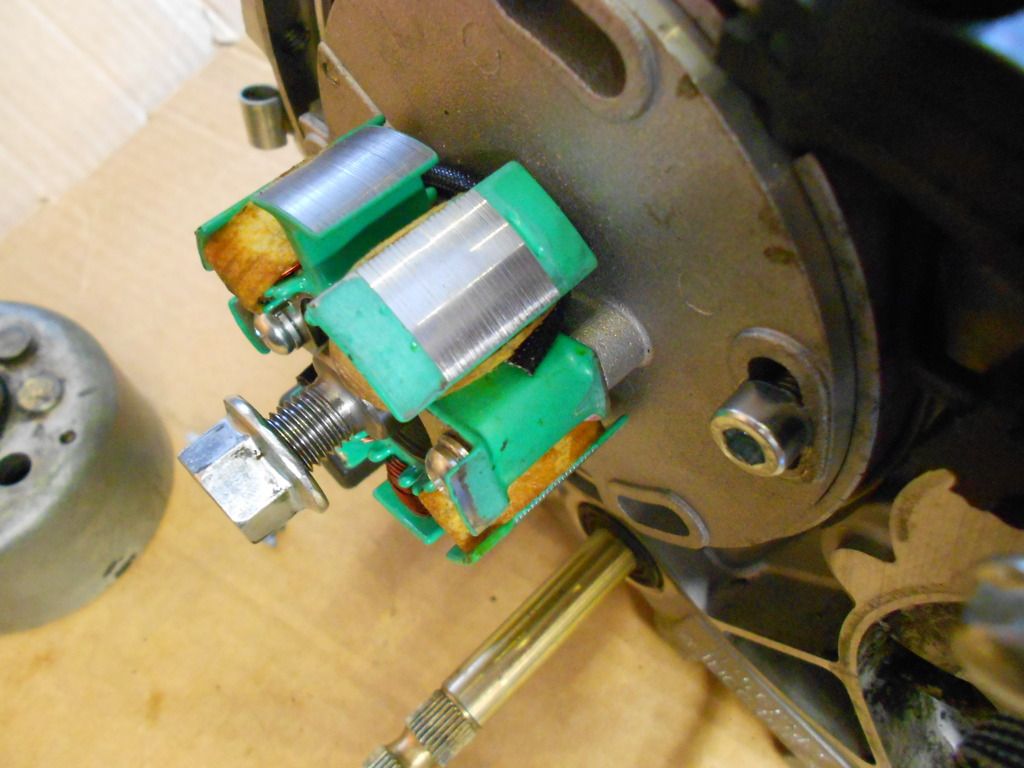

The engine side of the magneto thread looks like there is a crack or something odd in it or just tap and die set wore down at the factory.

The yx 140 engine is clean clean., but it needs a hone and a new piston

DSCN4571_zps4us7o�2w.jpg Photo by mikkhanson | Photobucket

And finally a question. Do these 2 piece oil slingers break down quite often on those yx140 engines or I should mill down the lifan 140 oil slinger and use it on the yx140 engine just to be sure?

The engine side of the magneto thread looks like there is a crack or something odd in it or just tap and die set wore down at the factory.

The yx 140 engine is clean clean., but it needs a hone and a new piston

DSCN4571_zps4us7o�2w.jpg Photo by mikkhanson | Photobucket

And finally a question. Do these 2 piece oil slingers break down quite often on those yx140 engines or I should mill down the lifan 140 oil slinger and use it on the yx140 engine just to be sure?

$17.71

$19.76

BBB Cycling BBL-52 MiniSafe Compact Bicycle Lock for Mountain, Road and Racing Bikes

Amazon Global Store UK

$150.99

For ATV Dirt Bike Scooter 49CC 2-Stroke Mini Complete Engine Motor With Gear Box

Eddie kaora

Nah just used the old piston and lifan 150 rings (had to cut off about 3mm off the ring ends, to make em fit). But it smokes a lot still. Seems to be the head gasket, because the steel liner has moved up in the cylinder somehow and that could be the cause. Or it is just the valve stems seals.

Little bit of updates. Ordered the piston and new valves etc few weeks ago. Should get them soon. The bike rides good, expect that I bent the front whee while landing on a tree root in the forest, the swingarm needs new bushings to be machined on a lathe and the upper shock mount on the frame is worn (thinking of welding 2-3 washers on each side of the frame to prevent it from wearing out prematurely. The subframe sits a cm higher, than it should be, but it is not a big issue.

The rear shock is just excellent. The front end feels a bit harsh. I hope that I can buy a cheap 80/85cc with grenaded engine and part it out, but keep the rolling frame and convert it to a pit bike engine or just keep the swingarm, suspension and make a pit bike frame myself.

What is even better, I might get the chance to snap up 14" front wheel with cnc hub and Marzocchi genuine non adjustable shivers for just 25 euros . But the tire on that wheel is worn (no big issue) and the forks are leaking. Maybe somekind of chromed hydraulic tube in 35mm exists and it could be just the matter to taking it onto a lathe, to make the bushing grooves. The 35mm seals and bushes should be cheap-cheap (about 5 usd for set of seals, the bushes are maybe 10.

. But the tire on that wheel is worn (no big issue) and the forks are leaking. Maybe somekind of chromed hydraulic tube in 35mm exists and it could be just the matter to taking it onto a lathe, to make the bushing grooves. The 35mm seals and bushes should be cheap-cheap (about 5 usd for set of seals, the bushes are maybe 10.

If those zokes are 660mm then I will use them on my upcoming 12/10 A-swingarm build (already have the elka, somekind of aluminium A-swinger. But I have still the engine to choose - either yx140 or Lifan 150 frankenengine (I have a lifan 150 crank in excellent shape, but It has a bad rod, maybe 110cc rod or similar will fit with other cylinder). Best case scenario would be using 120cc crank and Daytona crank gear to get engine with 55.5 stroke and 52.4 bore.

I have that weaker kind of aluminum A swinger, but I want a stronger one.

Like that:

The rear shock is just excellent. The front end feels a bit harsh. I hope that I can buy a cheap 80/85cc with grenaded engine and part it out, but keep the rolling frame and convert it to a pit bike engine or just keep the swingarm, suspension and make a pit bike frame myself.

What is even better, I might get the chance to snap up 14" front wheel with cnc hub and Marzocchi genuine non adjustable shivers for just 25 euros

If those zokes are 660mm then I will use them on my upcoming 12/10 A-swingarm build (already have the elka, somekind of aluminium A-swinger. But I have still the engine to choose - either yx140 or Lifan 150 frankenengine (I have a lifan 150 crank in excellent shape, but It has a bad rod, maybe 110cc rod or similar will fit with other cylinder). Best case scenario would be using 120cc crank and Daytona crank gear to get engine with 55.5 stroke and 52.4 bore.

I have that weaker kind of aluminum A swinger, but I want a stronger one.

Like that:

Got the valves and piston. Replaced them and the bike has lots of compression. It is quite rideable, but I need to change the seat foam to better one. And the swingarm bushings are still worn (sideways). The r6 rear shock is just excellent. I will take few pics of the bike in a few days.

![LISEN Bike Phone Holder, [2025 Upgrade] Motorcycle Phone Mount, Bicycle Phone Holder, Handlebar Phone Mount, Dirt Bike Accessories, Bicycle Accessories, for iPhone Samsung Google Pixel, Black](https://m.media-amazon.com/images/I/41FJGrZQ5ML._SL500_.jpg)

![Lamicall Motorcycle Phone Mount Holder - [Dual Vibration Dampener] [Upgrade Handlebar Clip] Motorcycle Cell Phone Holder, Bike Phone Mount, Fit iPhone 16/15/14/13 Pro Max, 4.7-6.7" Phones, Black](https://m.media-amazon.com/images/I/41bnoU+bpuL._SL500_.jpg)

![Zewdov Motorcycle Phone Mount, Upgrade Bike Phone Mount [1s Lock][Secure Protection], 360° Rotatable Phone Holder for Mountain Bike/ATV/Scooter Handlebar, Compatible with iPhone/Samsung 4.7-6.7"](https://m.media-amazon.com/images/I/51lvX8e2C3L._SL500_.jpg)

![JOYROOM Bike Phone Holder Mount, [Anti Vibration] Bicycle Phone Mount, Dirt Bike Accessories for All 4.7-7.0" Phones, Motorcycle Phone Mount for iPhone 16 Pro Max/15/14/13/12 Samsung S25 Ultra/S24/S23](https://m.media-amazon.com/images/I/41MPtPvknUL._SL500_.jpg)