wellll... i was planning to machine the front axle, due to the fact it was manufactured incorrectly, so what do you do when you have access to a horizontal mill? you FIX IT!!

but thats the rear axle I'm covering...? ok so i had planned on painting the ends of the axel's just so it looked tidy....

So here is the axle up on the mill bed in a special chuck... cant exactly remember what its called

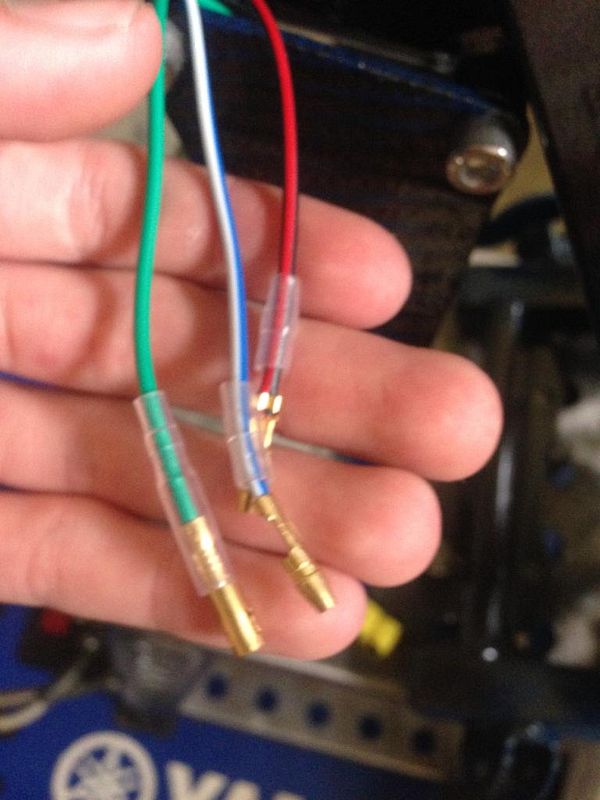

So wait why did i machine down the end? well what was happening was the socket was getting really stuck on the end.. like i had to hit it with a hammer to get it off.. fun!! the socket was also biting into the hex points... as you can see below...

the socket was also biting into the hex points... as you can see below...

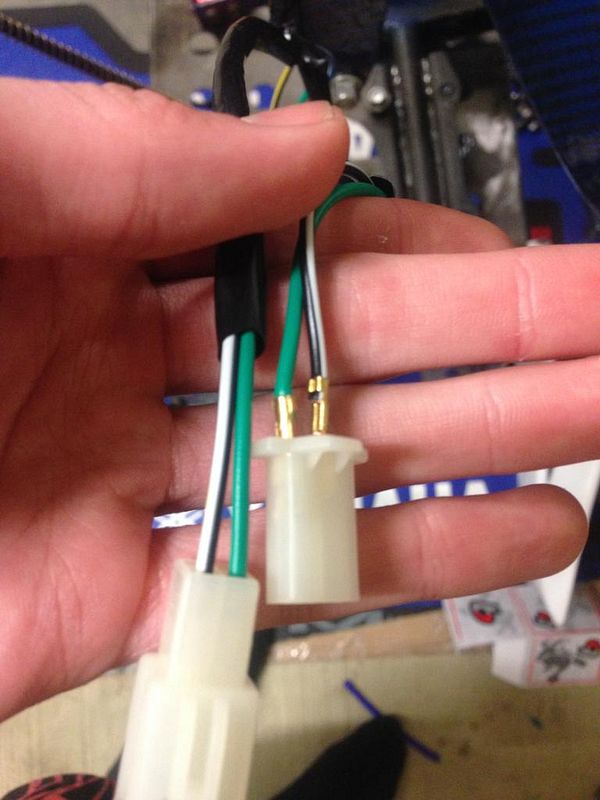

So here you can see that I have made a full pass on the axle... I found that i was 0.22 of a mm out... so i fixed that up and she fits very snug!

Below you can see how bad the part once was... ie the "corroded" and the "mill" "finish

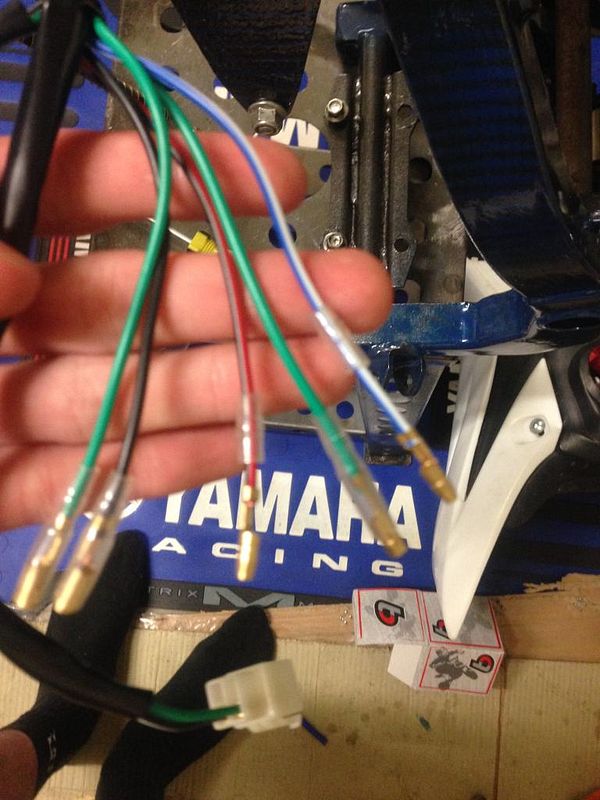

now for paint.... welllllll i had to go alloy finish paint... because i reckon it gives it a bit of "factory finish" to it and it doesn't make it an eyesore.. also sandblasted the ends and spacers and head of the bolts... i left the actual axle shank alone as you are meant to keep it as shiny as possible..

also sandblasted the ends and spacers and head of the bolts... i left the actual axle shank alone as you are meant to keep it as shiny as possible..

this one is a bit blurry but you should get the jist of it!

Stay Tuned!!!

but thats the rear axle I'm covering...? ok so i had planned on painting the ends of the axel's just so it looked tidy....

So here is the axle up on the mill bed in a special chuck... cant exactly remember what its called

So wait why did i machine down the end? well what was happening was the socket was getting really stuck on the end.. like i had to hit it with a hammer to get it off.. fun!!

So here you can see that I have made a full pass on the axle... I found that i was 0.22 of a mm out... so i fixed that up and she fits very snug!

Below you can see how bad the part once was... ie the "corroded" and the "mill" "finish

now for paint.... welllllll i had to go alloy finish paint... because i reckon it gives it a bit of "factory finish" to it and it doesn't make it an eyesore..

this one is a bit blurry but you should get the jist of it!

Stay Tuned!!!

![LISEN Bike Phone Holder, [2025 Upgrade] Motorcycle Phone Mount, Bicycle Phone Holder, Handlebar Phone Mount, Dirt Bike Accessories, Bicycle Accessories, for iPhone Samsung Google Pixel, Black](https://m.media-amazon.com/images/I/41FJGrZQ5ML._SL500_.jpg)

![JOYROOM Bike Phone Holder Mount, [Anti Vibration] Bicycle Phone Mount, Dirt Bike Accessories for All 4.7-7.0" Phones, Motorcycle Phone Mount for iPhone 16 Pro Max/15/14/13/12 Samsung S25 Ultra/S24/S23](https://m.media-amazon.com/images/I/41MPtPvknUL._SL500_.jpg)

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)

![Zewdov Motorcycle Phone Mount, Upgrade Bike Phone Mount [1s Lock][Secure Protection], 360° Rotatable Phone Holder for Mountain Bike/ATV/Scooter Handlebar, Compatible with iPhone/Samsung 4.7-6.7"](https://m.media-amazon.com/images/I/51lvX8e2C3L._SL500_.jpg)